Vapor compression at a new level

Further proof of PILLER's development competence

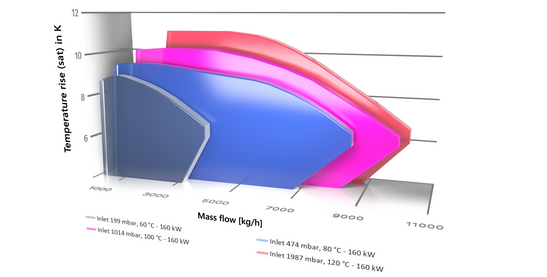

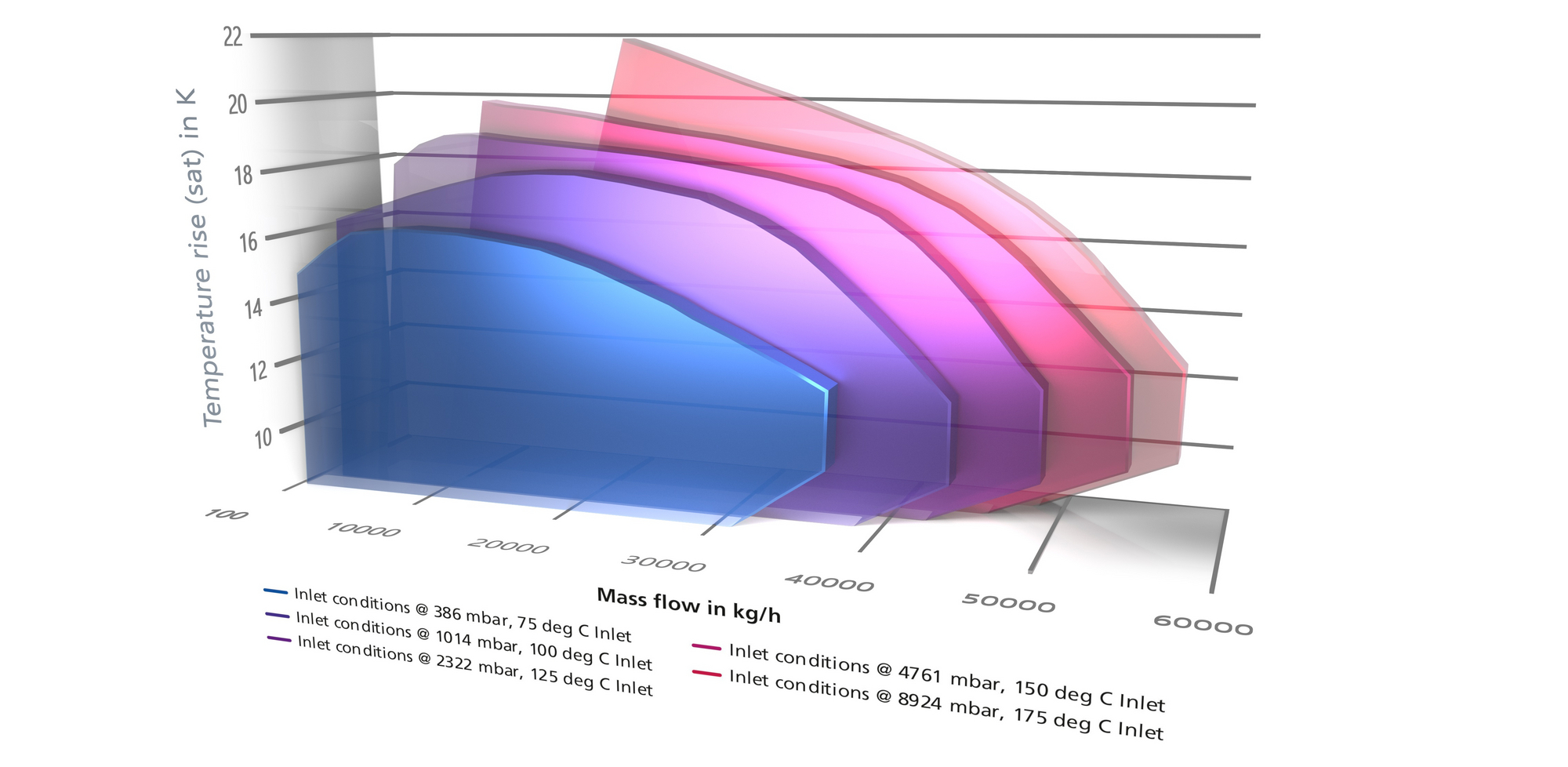

Design parameters for vapor applications

Performance features

- Performance up to 20 K temperature rise in single stage application

- Pressure up to 20 bar (g)

- Temperature up to 215 deg C

- Mass flow range up to 57 000 kg/h

Design Features

- All wetted parts out of material stainless steel

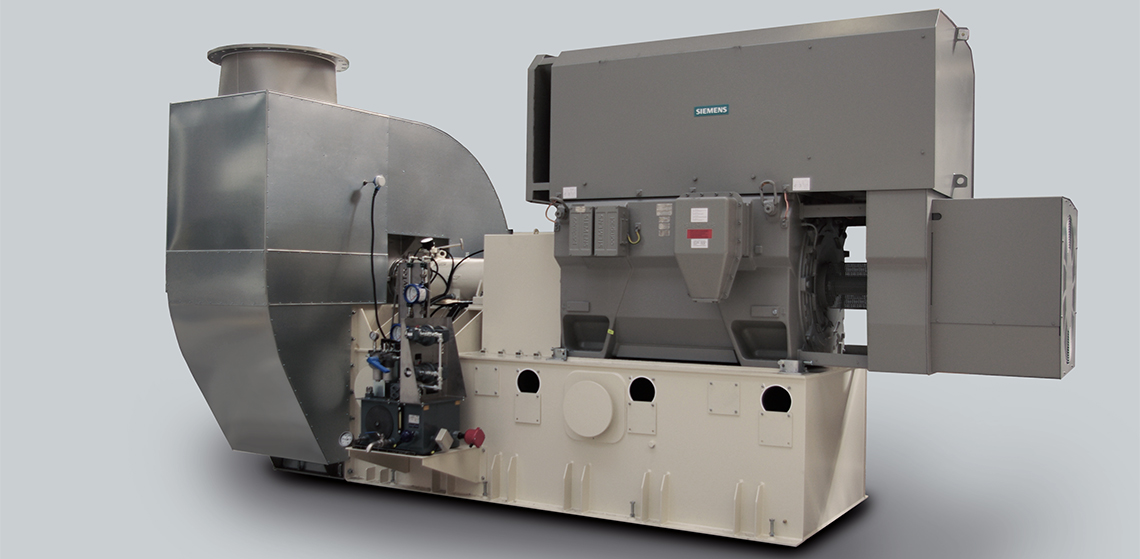

- Pull-out rotor unit

- Shaft sealing system with water or vapor buffering

- Suitable for hazardous areas

- Anti-Surge Control and adaptive Surge Protection for safe operation

- On-skid terminal box for central signal collection

Special features and design

Combining the advantages blowers with advanced performance of compressors

With the VapoMaxX, PILLER developed a new solution for the field of mechanichal vapor (re-)compression (MVR/MVC).

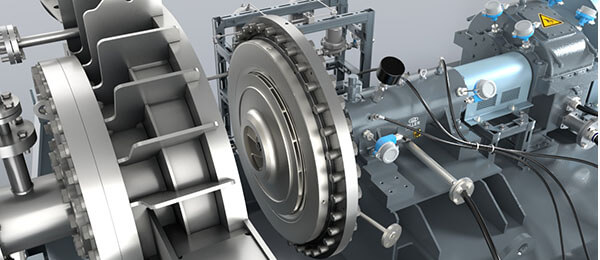

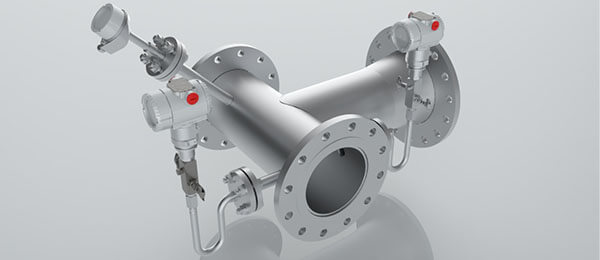

Pull-out rotor unit

For easy maintenance and service, PILLER installed a pull-out rotor unit: PILLER has designed a movable base which includes all rotating components – with mechanical crank. Vapor pipes can stay in place for shortest downtimes.

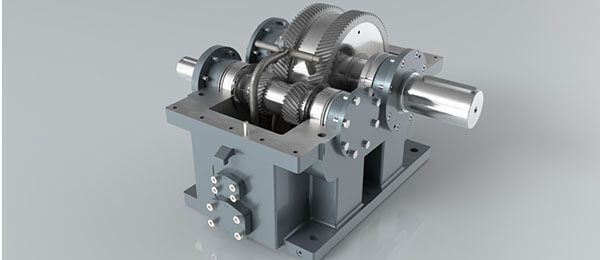

Gearbox

The gearbox is developed as a double helical gear design, leading to a smooth power transmission and significantly reduced noise emission. Equipped with instruments for monitoring of bearing temperature, vibration, and oil flow, it can be embedded into any safety monitoring.

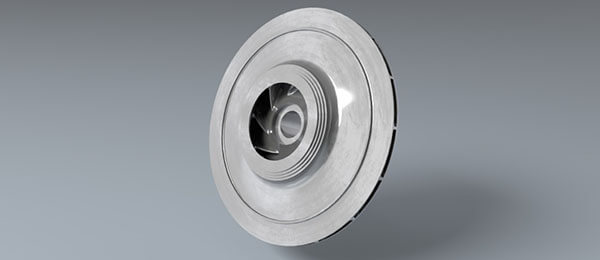

Optimized impeller design

The design of our impellers is constantly being optimized. New performance requirements demanded a special impeller design for all VapoMaxX types. For this development, new manufacturing processes were additionally tested and established.

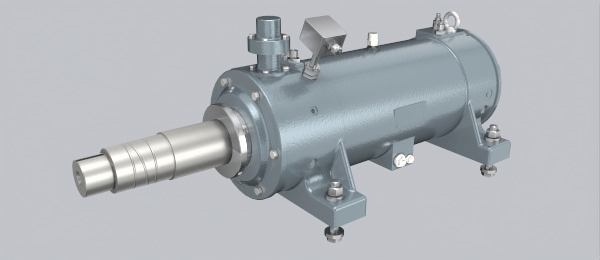

Squeeze Oil Damper Bearing

To either increase the stiffness of the bearings so that the safety margin to the critical speed is big enough for a safe operation or soften the stiffness for a supercritical operation, PILLER invented an off the shelf solution: the Squeeze Oil Damper.

Surge Control & Protection

For smooth, safe, and reliable operation, a Surge Control and adaptive Surge Protection System are installed. This monitoring systems automatically trigger the opening of control valves - either to maintain the minimum flow rate or to prevent successive pump surges.

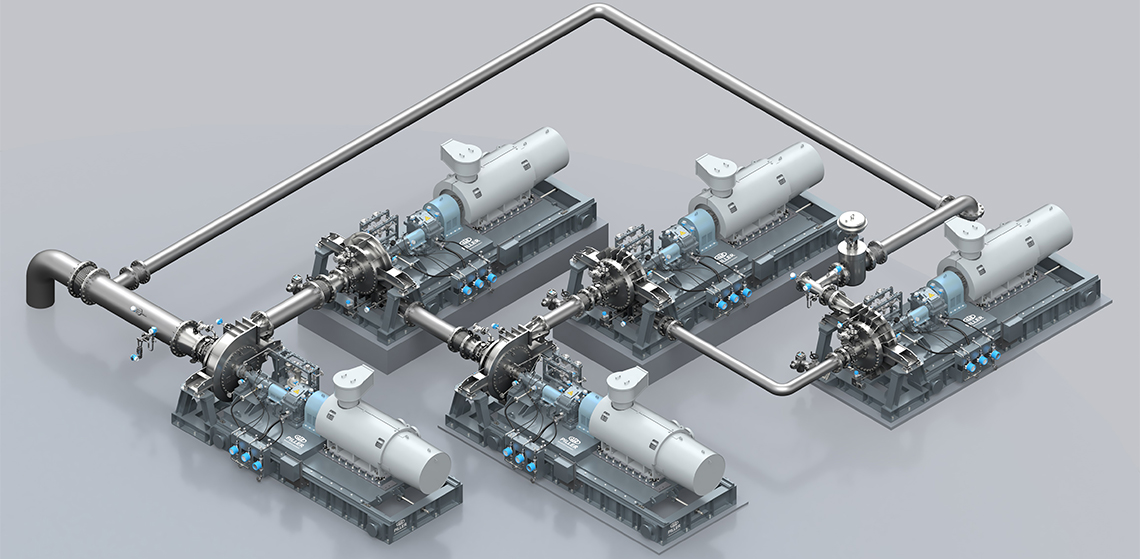

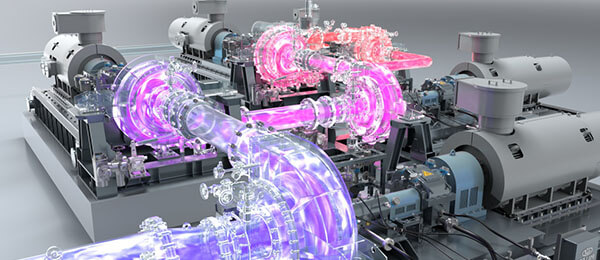

Multi-stage systems

The unique geometries and sizes of the VapoMaxX allow single-stage as well as multi-stage installations to maximize compression ratios, respectively to reach highest temperature lifts.

Optimized design for flexible installation options

PILLER designed a completely new combination of the advantages of high-performance blowers and the advanced performance of compressor technology into a design that allows very flexible installation and arrangement options for single- and multi-stage VapoMaxX systems. Systems with one or more VapoMaxX can be installed in existing platforms, even at higher heights.

Installation on platforms – for retrofit or new plants

The VapoMaxX is therefore particularly well suited for brownfield projects, the retrofitting of existing plants. Additionally, valuable space on the ground is released when building new plants. By this, PILLER can serve individual customer requirements regarding temperature and pressure rises and adapt the system’s design to the conditions in the customer's production plant.

Short maintenance and service times

Regardless of the installation site, which at first glance might appear difficult to access, the design of the VapoMaxX with its pull-out rotor unit ensures the shortest possible downtimes in production:

The access to the impeller is possible in the shortest possible time, so that neither additional cranes nor large teams are required for maintenance and necessary repairs. In addition, the piping remains in place so that leak tests after reconnection are not necessary.

Energy savings and reduction of CO2 emissions in the process industry

Redefining the level of reusing waste heat in the process industry

With the VapoMaxX, thermal energy from the previously unused waste heat released at the end of a production process is used to ultimately provide steam with a higher pressure and a significantly higher temperature for processes.

We serve different projects with our vapor compression heat pump technology, which is our response to rising energy costs. The results of one of our most recent projects: With an eight-stage VapoMaxX system, the savings in primary energy are eight million Euros per year and the CO2 reduction is 10,650 tons per year.

More PILLER Products

Contact

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271