Process gas handling – Made by PILLER

For a wide range of industrial applications

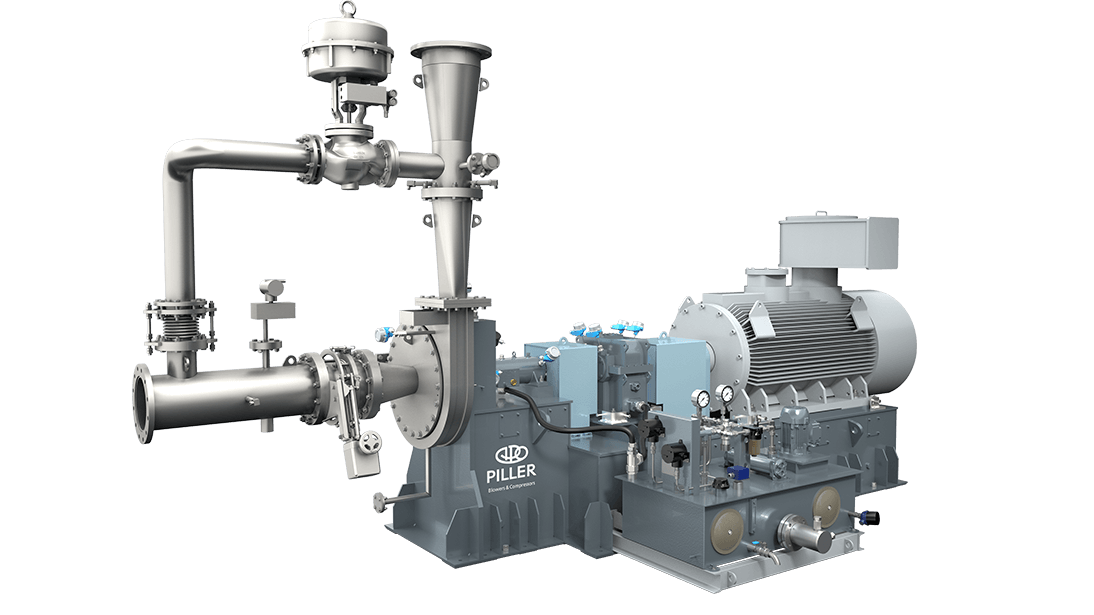

We unite high efficiency with best performance: Intelligent design, high-precision and quality workmanship make the selection of a PILLER Process Gas Blower the perfect choice in almost any application where high pressure, high temperature or a combination of both is required.

Using special components, materials and coatings guarantees optimal results even in extreme industrial services, e.g. including corrosive gases.

Benefits of Process gas blowers

Utilized in all industries

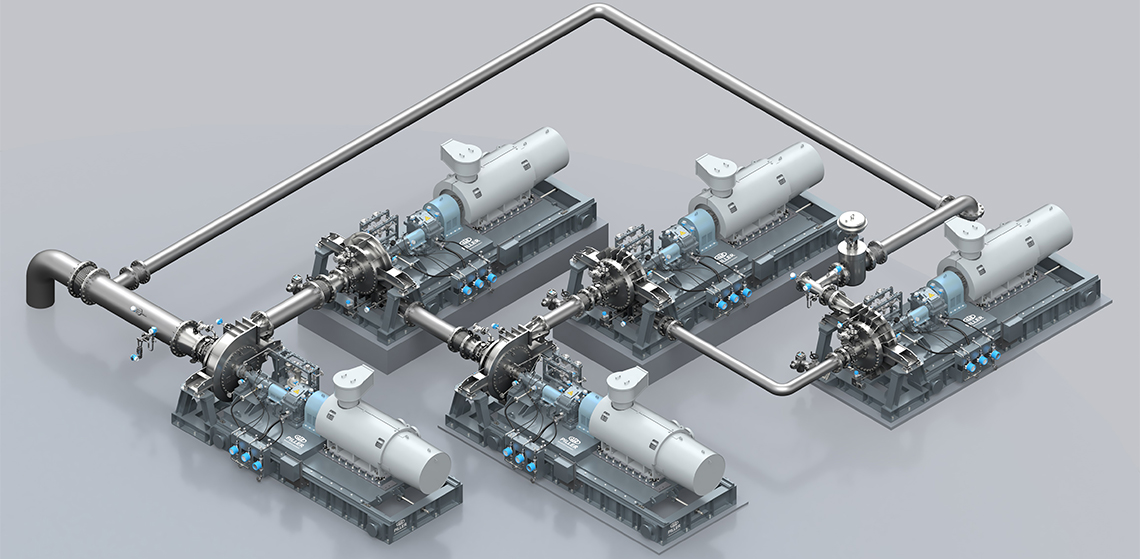

Process gas blowers – made by PILLER – are uniquely suited for the demands of any industry. Our state-of-the-art designs start with an optimized casing and impeller that are matched with the required shaft sealing system and the best fit bearing and lubrication systems including but not limited to our patented squeeze oil damper bearing system. This combined with our expertise in fabricating blowers from wear and corrosion resistant materials make PILLER Blowers the perfect solution for challenging gases containing corrosive products or abrasives.

Gas blowers for improved process efficiency

Transport and compression of gases are core operations in process technology. Wherever these operations are used in process technology, the blowers become critical to production. The design and quality of our PILLER Process Gas Blower systems are a key factor in unit operation availability, safety, efficiency and cost-effectiveness. They form the vital core of an optimized technical solution for the end user‘s production process.

Gas blowers for reduced energy consumption

Today, process designers and developers have a paramount priority: increasing efficiency and reducing operational costs. Constantly rising energy costs are pushing process designers to always be concerned about efficiency. The trend here, e.g. in the evaporation process, is towards higher pressure rise, smaller heat exchange surfaces and less energy consumption. Our experienced engineers understand the challenges of your process and overall market conditions: PILLER Process Gas Blowers are specifically designed for increasing process pressures and temperatures efficiently – and thereby significantly reducing energy costs for a process.

PILLER offers more blower types than any other blower manufacturer: Many years of expertise enable us to achieve the ideal interaction between efficiency, cost optimization and reliability for unsurpassed performance and high ROI. The keys to the ideal overall system solution: intelligent design, precision manufacturing and superior service.

Applications & performance data

Process gas blowers in PILLER Quality

PILLER Process Gas Blowers are custom designed for industrial applications and processes. Our expertise in high alloy materials, high temperature applications, processes and blower performance helps us to provide the perfect solution for your process. Extreme conditions such as the high temperatures of CCR (Continuous Catalyst Regeneration) blowers with up to 600 degC, Sulfuric Acid Production, Continuous Polyamid 6 Production and many more are proof of PILLER Blowers reliability and performance.

Wide range of process applications

Numerous references in different applications and production methods confirm our position as technology leader and expert: providing a reliable state-of-the-art product that meets your demands.

Blowers are used in various areas of the plant, e.g. in the petrochemical industry. Any of these customized applications require high-performance blowers that are designed for reliability, easy maintenance and dependability.

| Performance Data | |

|---|---|

| Fluids | Air / Gas / Gas mixtures |

| Volume Flows | from 400 m³/h to 1.100.000 m³/h |

| Differential pressure | single stage up to 50 kPa (on atmospheric air) |

| Inlet temperature | from -180 degC to 1200 degC |

| System pressure | from 0,1 bar abs. to 30 bar; depending on the size of the casing – smaller casings can handle even more pressure |

Process gas blowers for toughest conditions

Under the toughest operating conditions, PILLER Process Gas Blowers combine efficiency with robust construction for reliability to ensure smooth continuous process and ease of maintenance.

When it comes to abrasive, corrosive, high temperature or combustible gases and gas mixtures, we offer application-specific solutions for your operating conditions.

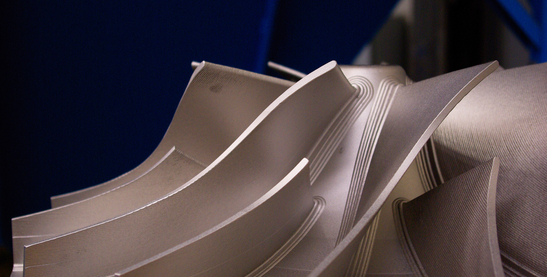

Efficiency optimized blower design

- PILLER specializes in centrifugal fans and blowers

- Maintenance-friendly due to modular design with accessibility to the individual components for easy replacement

- ATEX Zone 1 and 2

- Pressure-resistant and pressure-shock-resistant design: according to Pressure Equipment Directive

- Leakage-free version: seals can be provided with a sealing gas connection, blower casing in gas-tight design possible and flange connections are available with appropriate seals

- Water injection for heavy material build-up (caking); self-cleaning during operation possible

Durability focused material selection

A wide range of special materials is available for your application:

- Duplex and Super Duplex with high corrosion resistance and good strength values

- Hastelloy®, Inconel®, and titanium for particularly aggressive environments, or for reducing media, such as acids of different concentrations or extreme temperatures

- for high temperature blowers, Nickel alloys such as Inconel®, Incoloy® and Hastelloy® are common choices between 600 and 1000 degC

- surface protection against corrosion and wear of parts in contact with media by using paint systems and protective coatings, such as Halar®

PILLER Quality standards

- Welding of special alloys like Titanium, Hastelloy, Inconel, etc.

- Manufacturing according 2014/68/EU European Pressure Equipment Directive(PED)

- Declaration for CU TR-CU 010/2011, TR-CU 020/2011 and TR-CU 004/2011

- Experience and expertise to meet API (American Petroleum Institute) 560 and API 673 specifications

More PILLER Products

Contact

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271