Compact solution for MVR Systems

Mass flows between 200-9,000kg/h

PILLER offers a modular solution for low mass flow rates in MVR applications, thus expanding the product range with the VapoFan, a product of our VapoLine.

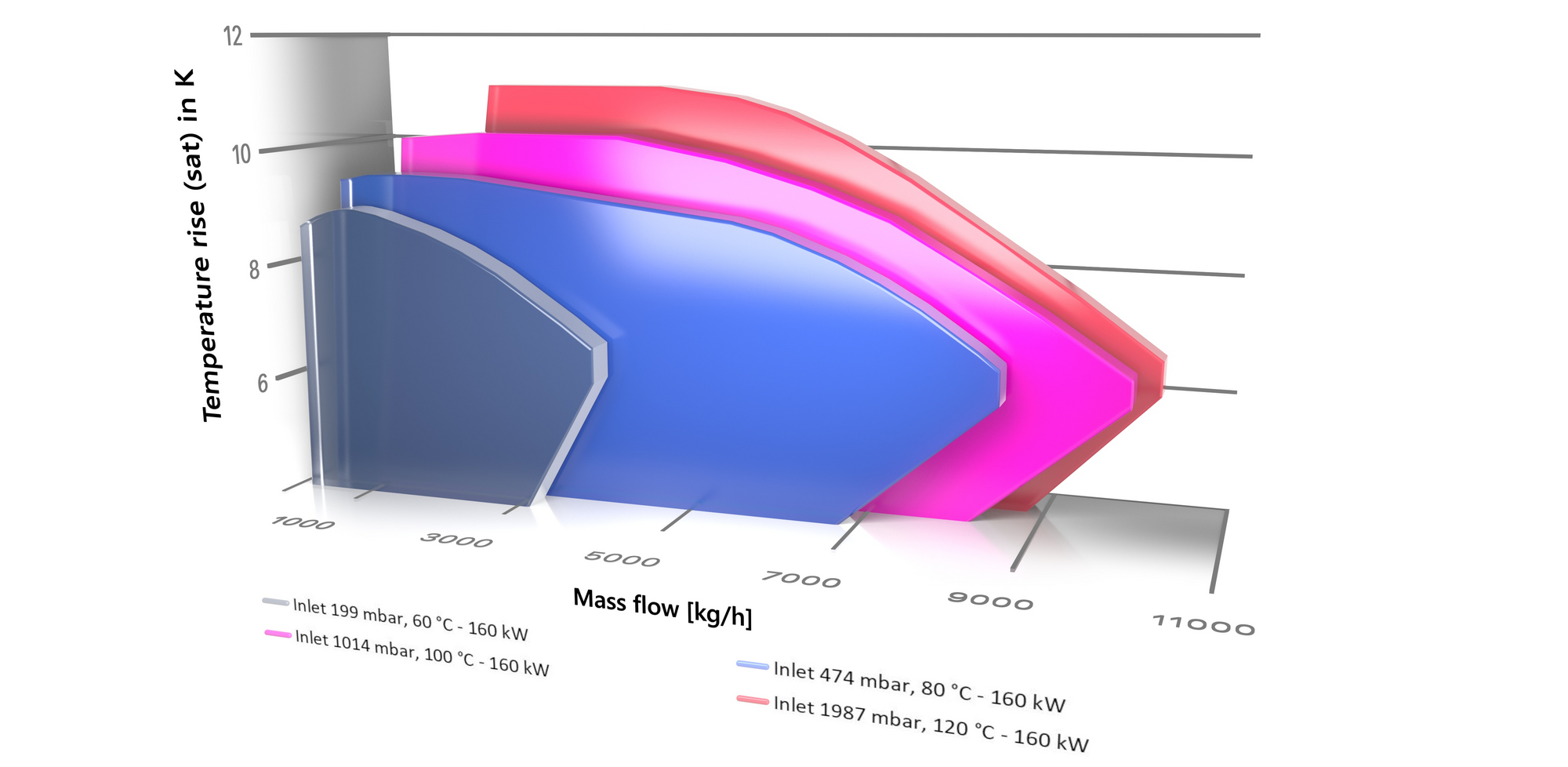

As a vapor compression unit, PILLER's VapoFan is specifically designed for applications from approx. 200 to 9,000 kg/h mass flow with a temperature rise of 11 K in single-stage applications.

Advantages of our VapoFan for Mechanical Vapor Recompression

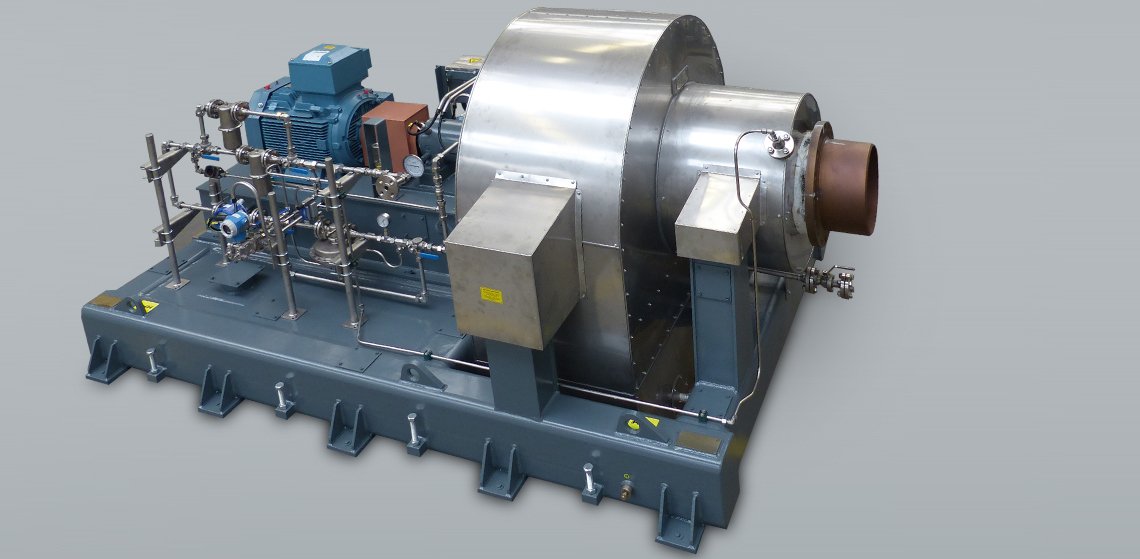

Vertical blower design for compact evaporator systems

The VapoFan is ideally suited for integration into a compact evaporator system: with minimal space requirements, independent installation locations and less energy consumption.

The perfectly harmonized drive unit is one of the reasons for the excellent efficiency. It consists of a synchronous motor specially developed by PILLER and a matching frequency converter in various capacities. A wide range of customer requirements can thus be covered and served.

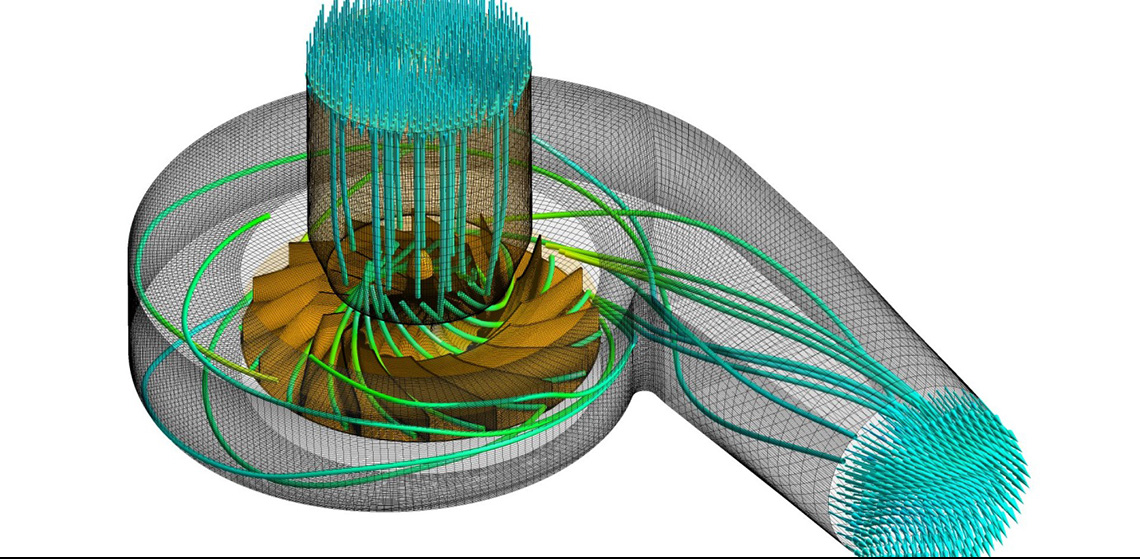

The design of the VapoFan as a radial blower ensures reliable and smooth operation. The clearance dimensions between impeller and housing are sufficiently large to avoid any contact. Compared to rotary lobe blowers, PILLER VapoFans have an additional advantage: the flow is much more stable and the efficiencies remain constant within the wide operating range. The efficiency is up to 86% due to the ideal matching of motor and blower.

| Our VapoFan at a glance: |

|---|

|

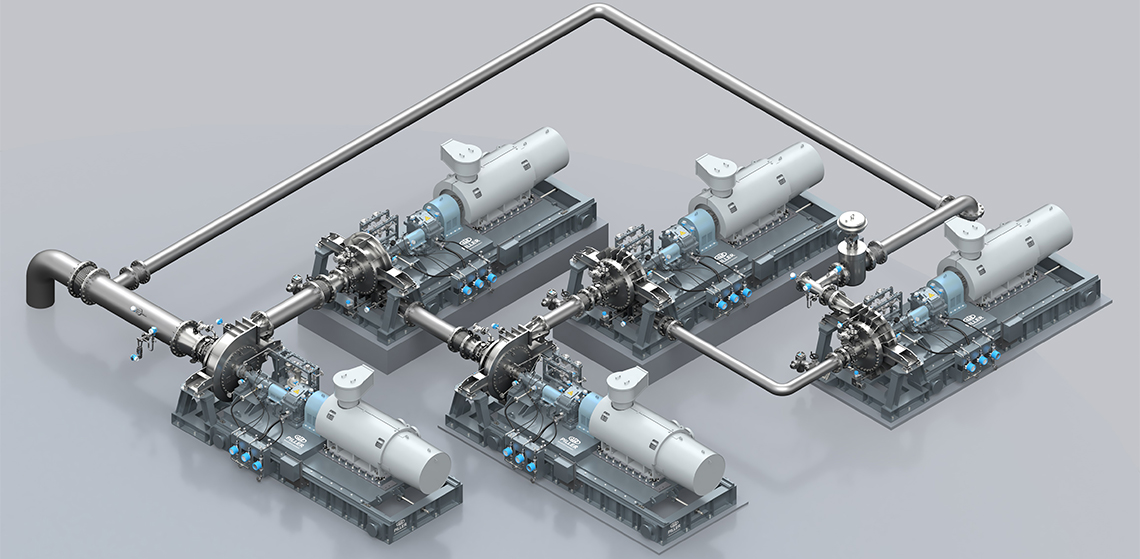

The PILLER VapoStation

Our innovation for serial connected VapoFans in MVR applications

The PILLER VapoStation is a new and innovative PILLER solution for serial connected VapoFans in Mechanical Vapor Recompression (MVR) applications, built on the reliable and efficient blower technology. With its compact and modular design, the VapoStation offers a unique combination of performance, efficiency, and accessibility.

Key features of our VapoStation

- Compact and modular design connected in series for easy maintenance and service

- Flexible arrangement in combination with less space requirements

- Designed for your specific process requirements and reliable operation

- Base frame and connecting pipes with flexible joints included in scope of supply

Features of our VapoFan

- Wide range of processes and applications

- High-performance in terms of efficiency, lifetime and temperature lift

- High quality materials are used for the requirements of the process industry

Build for low mass flows

Performance summary of our VapoFan

The VapoFan is the ideal solution for any steam compression with low mass flows. This includes applications of Mechanical Vapor Recompression such as

- Distillation,

- Crystallization,

- High Concentration (including ZLD, applications for wastewater free production),

- Drying,

- or the use as booster for partial flows.

Efficient energy recovery solution for the process industry

The combination of limited energy sources with increasing prices and the goal to reduce greenhouse gas emissions are pushing the process industry to find more efficient solutions for its energy demand. Our VapoFan supports you to secure the optimum MVR vapor compressor solution for your specific process requirements.

The machine offers an ideal solution to upgrade existing plants but also for new plants and process extensions. The advantages: low space requirements, mobility of the equipment and fast implementation.

Another advantage our VapoFan offers, is that no grease can leak into the wetted area. Therefore, the blower is perfectly suited for applications in the food industries and for the pharmaceutical industries, e.g. Water For Injection (WFI).

The very flexible range of applications, due to the modular construction, offers numerous possibilities – also in innovative and visionary projects. In water treatment, the VapoFan is also suitable for unusual locations due to its compact design; for example, on board of ships or in the smallest modular plants for the treatment of industrial wastewater.

MVR Blower Design

Matched to your operation

- Ready to equip, also for serial connection of VapoFans with our VapoStation

- Synchronous motor exclusively developed by PILLER

- Self-lubricating bearings, operating lifetime > 40,000h

- Impeller directly on motor shaft

- Up to 315 m/s circumferential speed

- 4 version of electric drive electronics: 37, 55, 90, 160 KW

- Up to 11 K temperature rise in single stage applications

- Shaft seal design for water/vapor buffer or vacuum suction

- Improved protection and monitoring by instrumentation

- Dimensions and weights for each VapoFan unit

- Weight: approx. 400 kg - 700 kg

- Height: approx. 1.60 m - 2.30 m

- Width: approx. 1.50 m x 1.00 m

- Ambient temperature from -10 °C to 45 °C

- Casing design pressure: 0.1 bar(a) to 1.5 bar(a)

Learn more about PILLER

Contact

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany

![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271