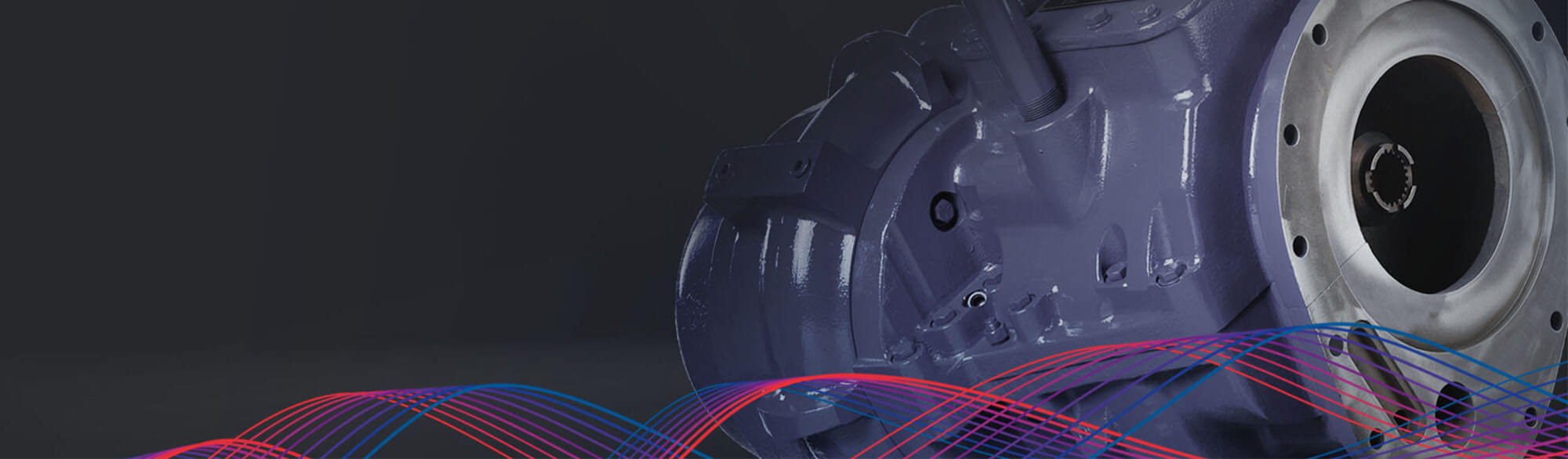

The PILLER A-Series Compressor

Turbine atomizing air compressor explained

PILLER Atomizing Air Compressors are small high pressure air compressors that are used on GE Gas Turbines fired by liquid or dual fuels. These compressors take a small amount air off the final stage of the gas turbine air compressor section and then boost that air to a higher pressure. This higher pressure air is fed back to the liquid fuel nozzles to provide for more complete and efficient combustion.

Benefits of the PILLER Atomizing Air Compressor

A rebuild compressor for GE Gas Turbines

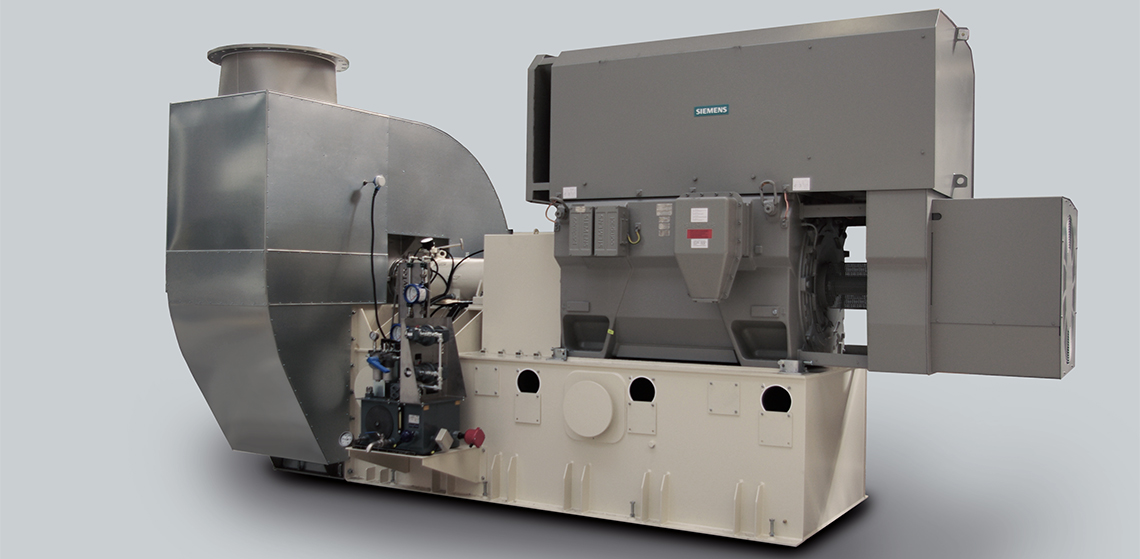

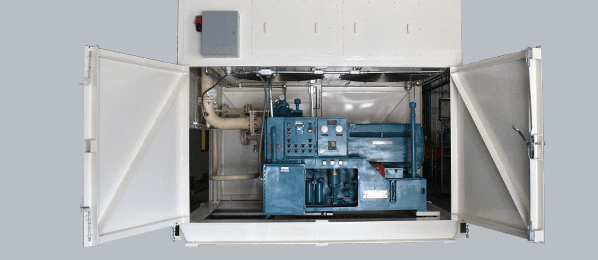

Our Atomizing Air Compressors are specifically developed to replace the original equipment Atomizing Air Compressors – in form, fit and function. The PILLER A-Series compressors are manufactured with the highest quality components and are expertly assembled in our Schenectady, NY facility. We deliver a complete, new, and tested compressor ready to drop in and install and will rebuild your existing compressor to as new condition and performance.

Rebuilt SC-6AA Compressor in a new PILLER enclosure with Air to Air Inlet Air cooler and Air to Oil Lube Oil Cooler and cooling fans.

are driven by the Gas Turbine Auxiliary Gearbox.

Highest Quality standards

- All New A-Series Compressors and PILLER Parts are built to the highest design standards and highest PILLER Quality for promised durability and longevity

- constant availability and short delivery times, resulting in less expensive downtimes

- most common A-Series parts in stock

- can be quickly installed with support of PILLER service team – by phone or on site

- affordable solution: better price than OEMs

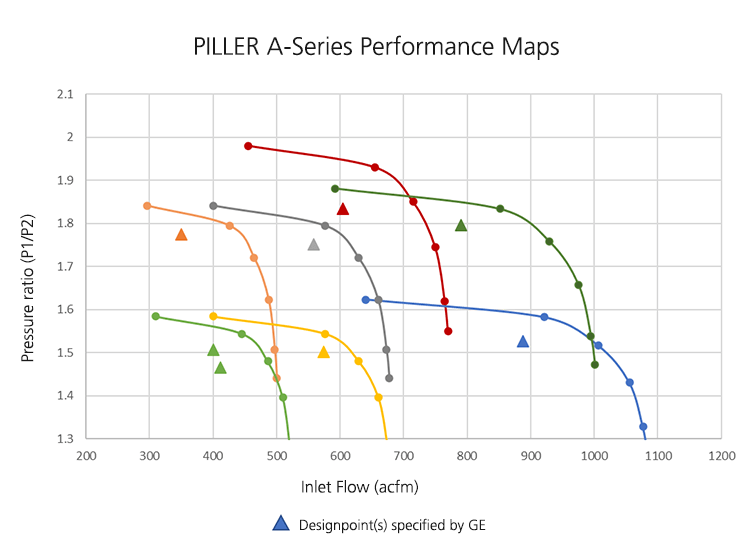

Atomizing Air Compressor performance data

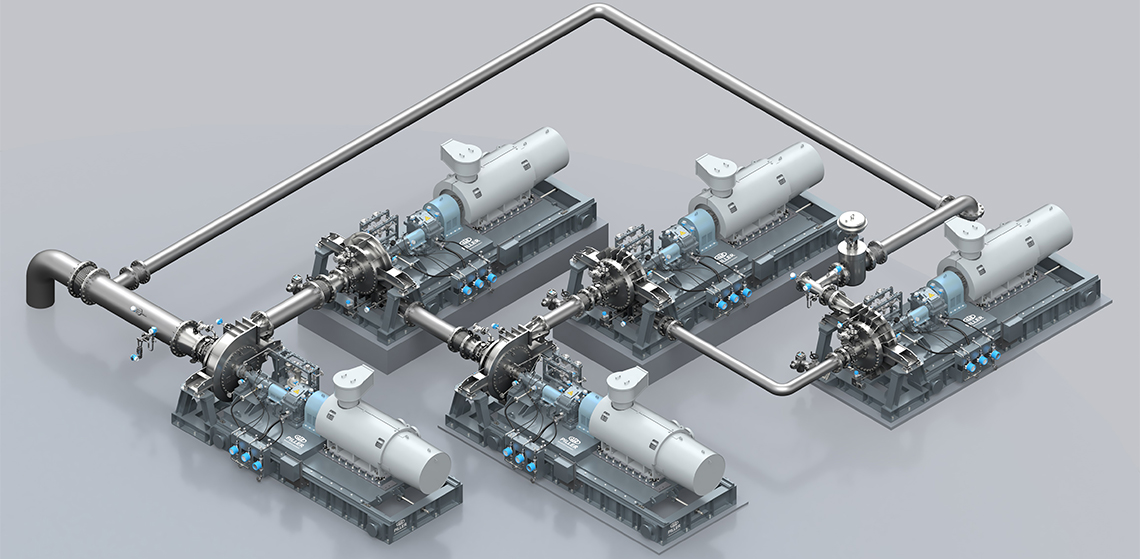

There are as many as 20 different performance variations of the PILLER A-Series compressor that are obtained by varying the impeller and shroud geometries. Please find in the adjoining list the most common Atomizing Air Compressors cross referencing the OEM part numbers.

Drop-In replacement for GE gas turbines

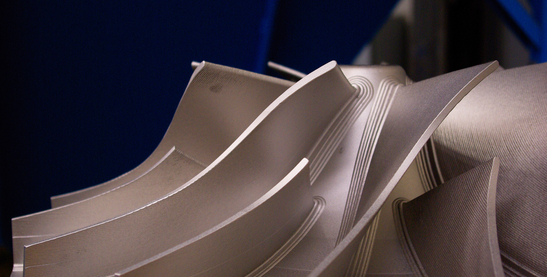

PILLER A-Series compressors are a drop-in replacement for Turbonetics or Atlas Copco SCF-6 compressors. A real alternative to the original equipped compressors: Only the highest quality parts are used, the impellers are 5-axis milled from aircraft quality precipitation hardened stainless steel, gearing is made to AGMA (American Gear Manufacturers Association) Q-13 quality and the inlet shrouds are CNC machined to match the impeller profile.

New A-Series Atomizing Air Compressors and PILLER Rebuilds of SC-6AA and SCF-6 compressors utilize the same precision high speed tilting pad journal bearing designed to ensure rotordynamic stability at compressor speeds in excess of 50100 rpm.

| PILLER Comp. Model | Original Assembly No. | GE P/N |

|---|---|---|

| PILLER A-136 | 806993G07 | 302A1537P005 |

| PILLER A-136 | 302A1537P005 | |

| PILLER A-110A | 806993G08 | 302A1537P004 |

| PILLER A-110B | 302A1537P006 | |

| PILLER A-164A | 806993G06 | 302A1537P001 |

| PILLER A-164B | 302A1537P10 | |

| PILLER A-164C | 806993G17 | 302A1537P12 |

| PILLER A-124 | 806993G10 | 302A1537P009 |

| PILLER A-124B | 806993G16 | 302A1537P11 |

| PILLER A-133 | 806993G15 | 302A1537P007 |

Gas Turbine support

Efficiency, maintenance costs and machine availability are among the most important concerns when operating gas turbine plants.

With PILLER, you have the expert at your side. Besides developing our own A-Series Atomizing Air Compressor, we offer spare parts, service and shop repairs and overhauls.

Typical Scope of Repair

Atomizing Air Compressors sent to PILLER’s workshop in Schenectady, NY, for rebuild receive:

- Complete inspection with tear down report and repair quotation

- NDT Inspection of critical high-speed rotor and gears

- Wear part replacement: Bearings, Seals and Gaskets

- Balance of rotors

- Expert shop assembly

- Full mechanical and performance testing to ensure ‘Plug & Run’ reliability

Learn more about the PILLER Atomizing Air Compressor

Further detailed information can be found in our product sheet on the Atomizing Air Compressor:

PILLER A-Series Atomizing Air Compressor

More PILLER Products

Contact

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271