Piller Blowers Technology (Taicang) Co. Ltd., China, a subsidiary of Piller Blowers & Compressors GmbH in Moringen, delivered the 500th high-performance blower to a regular customer at the end of July. Almost five years after the start of production, for Hao Pan, Managing Director of Piller Blowers Technology (BTT), and his local colleagues this is a reason to be happy: “We are proud of this important milestone. It is a success for the entire team at PILLER, as we also work hand in hand with our colleagues in Moringen.” The two managing directors of Piller Blowers & Compressors, Christoph Böhnisch and Stephan Merkel, are also very satisfied with the achievements so far. “From our point of view, the local colleagues are doing an excellent job. The product quality not only convinces us, but above all our customers,” emphasizes Christoph Böhnisch. Stephan Merkel adds: “Piller Blowers Technology in China was already in the black in the third financial year after the start of operative production and since then has been able to steadily increase its results. The delivery of the 500th machine is now the next big success.”

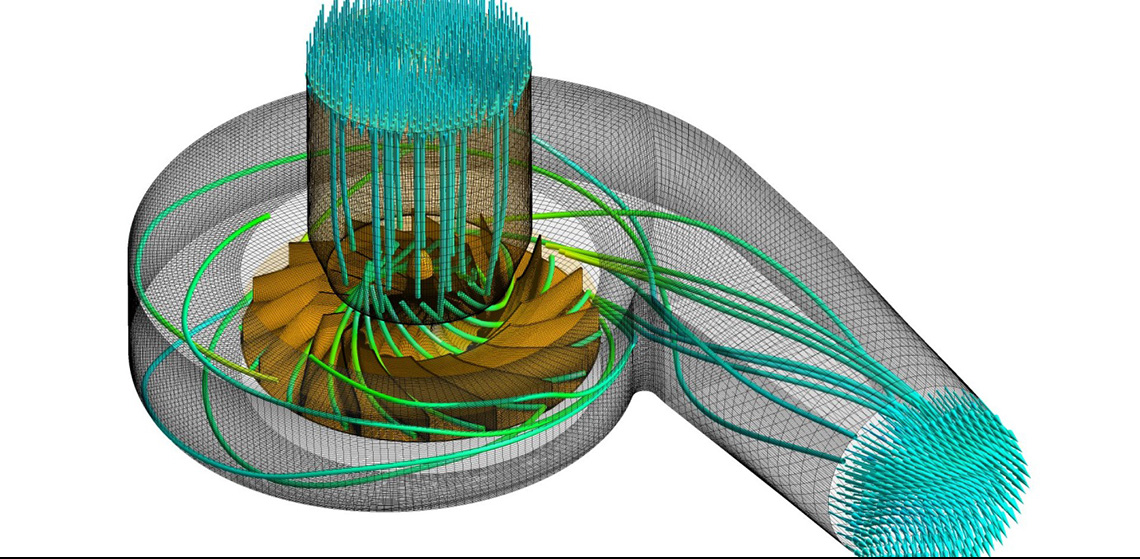

So far, BTT in China has mainly taken on the final assembly of the machines, but still manufactures a few parts itself. The rotating parts – the impeller, bearings and shaft seal – are manufactured in Moringen. The necessary housings come from BTT's own production or, like other parts, are made by Chinese suppliers. As soon as the parts have arrived in China from Germany, the impeller is balanced, blasted, checked and assembled with the other components on site. "After assembly, we test the machines on our own test bench before we deliver them," explains Hao Pan. In the future, an expansion of the vertical integration is planned: while the core components will continue to be supplied from Moringen, BTT is to manufacture more and more parts itself and thus reduce the dependency on Chinese suppliers.

PILLER has so far been able to achieve the goals associated with setting up a production site in China. “From a global perspective, expanding our worldwide production capacities was one of the goals. Above all, we wanted to achieve shorter delivery times for our Chinese customers and be able to carry out any necessary repairs on site,” explains Christoph Böhnisch. Savings in freight costs and customs duties were further reasons for investing in China. “Building on the achievements of Hao Pan and his team, we aim for further growth. We are planning to build up staff and also want to increase sales,” says Stephan Merkel. Together, the PILLER managing directors keep an eye on possible risks. "We are aware that we have to monitor both the economic and the political conditions in a local as well as global context. Piller Blowers & Compressors should grow in the long term and develop sustainably,” emphasizes Christoph Böhnisch. In the Asian economic area, this is to be achieved not only by expanding regional coverage, but also by expanding the customer sectors supplied. “There are considerations to supply other countries in Asia from China. In the production of bioethanol and generally where industrial heat pumps are used, there are great opportunities for us in China for the future,” Christoph Böhnisch points out. At the moment, BTT mainly supplies machines to the food and beverage industry, the cement industry and for industrial wastewater treatment processes.