A joint development project by Piller Blowers & Compressors GmbH and the TU Clausthal is being supported by the Federal Ministry of Education and Research (BMBF) with over 400,000 Euros in funding. Piller Blowers & Compressors GmbH has started a three-year development project with Clausthal University of Technology, which is funded by the Federal Ministry of Education and Research (BMBF) with over 400,000 Euros as part of the 7th energy research program "Innovations for the energy transition".

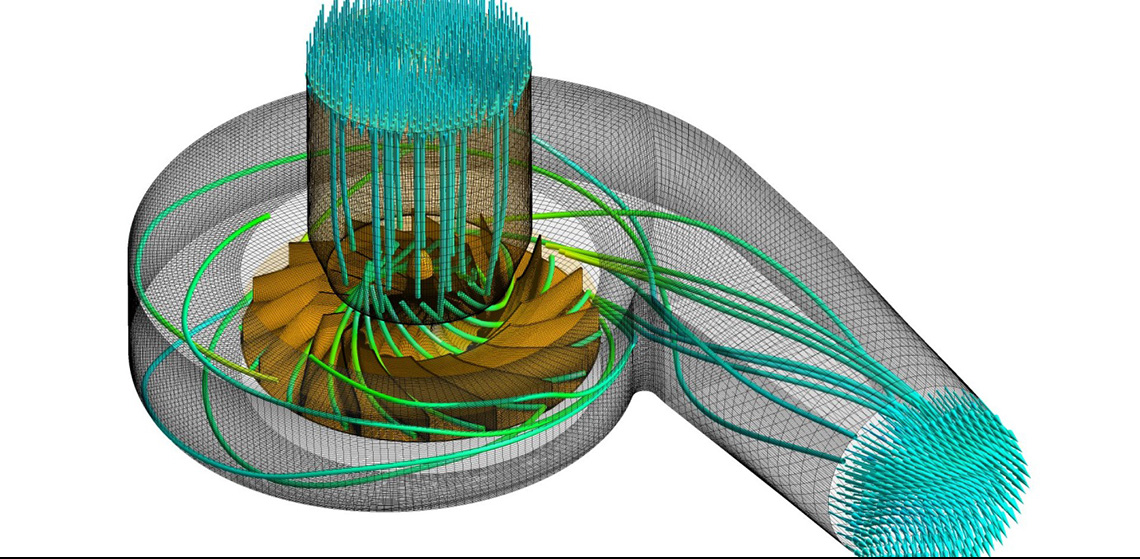

Research funding is an important building block in energy policy up to the year 2050, which aims to halve primary energy consumption compared to 2008. "Because we want to make an even greater contribution to this than before, we have started developing new technologies for turbo gears for an operating range of maximum 15,000 revolutions per minute and a maximum drive power of 900 kW together with the TU Clausthal," explains Philipp Kellner, Head of the Design at PILLER.

"With a package of measures consisting of innovative gearing, an integrated pressure collar and a sliding bearing that can be switched off, we want to reduce the power loss by more than 50 percent compared to the current design," emphasizes Hans-Joachim Ring, Head of Research and Development at PILLER. With the current energy mix, an additional 500 tons of CO2 savings would be possible over the entire service life of a machine. This CO2 savings potential per machine was one of the reasons for the funding - the cooperation with the TU Clausthal is another. The team at the TU Clausthal around Prof. Dr.-Ing. Armin Lohrengel has great expertise in the field of pressure combs and also has the necessary infrastructure for the test runs that are due later, which PILLER has already used to test other machine parts. "For us, the cooperation means the opportunity to take a holistic view of the pressure combs researched at the institute in the transmission environment and to test the results of basic research in application," emphasizes Prof. Dr.-Ing. Armin Lohrengel.

"It is planned to integrate the function of the squeeze oil damper used today into the transmission by means of a ‚disconnectable tilting pad bearing‘ in order to save the entire bearing of the squeeze oil damper as a module", adds Philipp Kellner. The big challenge here is the design and construction of the new bearing, which on the one hand has to provide the necessary damping and on the other hand must not produce any additional losses during operation. “In the future, we only want to use the new bearing to safely pass through the first bending-critical speed. It will be switched off in continuous operation,” explains Philipp Kellner. Piller Blowers & Compressors GmbH came up with the idea for further development because experience from customer projects has shown that energetic and process-related improvements to the gearbox are possible. “The goal is not just energetic improvement and further development. Because there is no supplier with whom this can be implemented, we have developed the ambition to ultimately produce the optimized turbo gear ourselves with our partners,” Philipp Kellner explains the ambitions at the end.

Thursday, 27. April 2023

PILLER and TU Clausthal receive funding