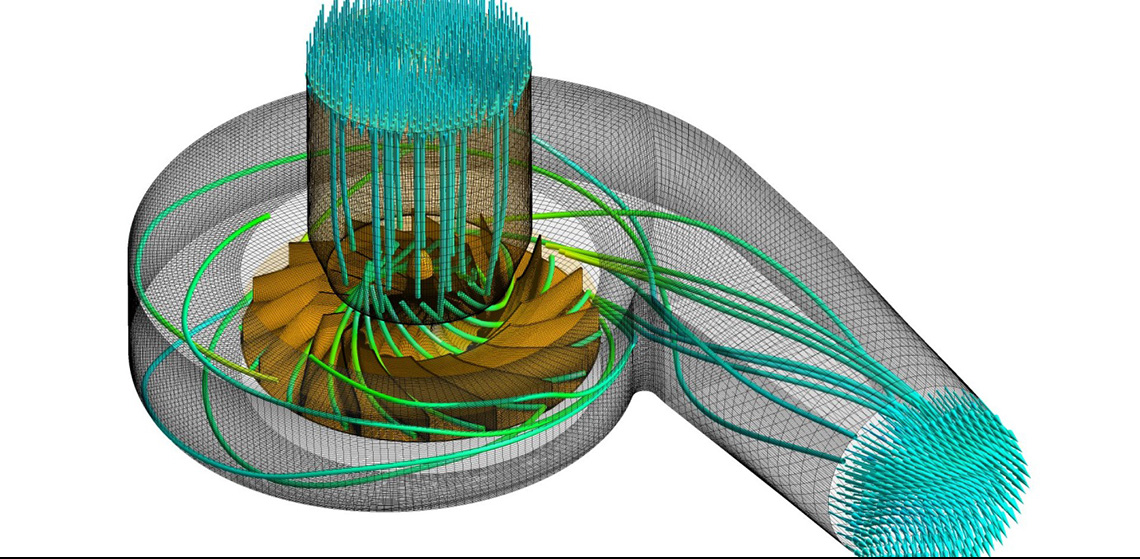

Piller Blowers & Compressors is a globally renowned technology leader for high-performance blowers used in Mechanical Vapor Recompression (MVR). Optimizing processes, increasing efficiencies, and enhancing performance are fundamental principles at PILLER. With an extensive R&D department, the company constantly develops new solutions for the international process industry. In 2020, PILLER released a powerful compressor series, thus expanding its product range.

This latest innovation represents the third product line in the steam and vapor compression range. Eight impeller configurations were specifically designed for steam and process gas compression, focusing on Mechanical Vapor Recompression. Efficiency and performance were the primary focus. "Our compressor series allows significantly higher temperature rises and is therefore highly recommended for customers of our industrial heat pump applications," says Dr. Steffen Kuberczyk, Global Sales Director at Piller Blowers & Compressors GmbH. "It meets exactly the requirements in high-temperature heat pumps: the range of applications is now significantly expanded, and even more energy and CO2 savings can be achieved by compressing steam using multiple machines in series."

The performance features at a glance:

- 20 K temperature rise

- System pressures up to 20bar

- Design temperatures up to 300 degC

- Drive power up to 1800 kW

This new generation of machines provides the advantages of high-performance blowers, extending PILLER’s range of applications. The result is a new product line designed for robustness, durability, and ease of maintenance.