When it comes to pressure increase, centrifugal blowers by Piller Blowers & Compressors lead the way. Like a blower in terms of design, the performance is akin to a single-stage, centrifugal turbo compressor. A wider operating range and easier maintenance, in addition to high operational reliability and simple operation ensure that the centrifugal blowers by PILLER stand out against turbo compressors.

They are suitable for countless applications that were previously reserved for turbo compressors, such as use in sulfuric acid production processes.

Nowadays, sulfuric acid H2SO4 is generally extracted using the double contact process. The starting point for sulfuric acid production is the generation of sulfur dioxide SO2, which occurs through the combustion of sulfur. Subsequently, catalytic oxidation turns SO2 into sulfur trioxide SO3, which is then processed into sulfuric acid in further steps.

The first process in the production of sulfuric acid SO2 is where the compressor comes in. Liquid sulfur is burned in a sulfur burner with the addition of air. The air is previously dehumidified in drying towers with 93-98% sulfuric acid.

The compressor conveys the pre-dried air, which also contains entrained acid from the drying tower, into the incinerator. The required pressure increase generated by the compressor is typically over 50kPa.

The use of technical sulfuric acid during production is a challenge for every compressor, and demands a high level of expertise. PILLER has developed its centrifugal blowers especially for use in sulfuric acid production, thus enabling the provision of solutions precisely tailored to customers’ requirements.

With its blower design, Piller Blowers & Compressors offers decisive advantages compared to compressors

Until now, single-stage turbo compressors have almost exclusively dominated in the sulfuric acid industry. The use of PILLER centrifugal blowers in a sulfuric acid plant in the Czech Republic shows that they can certainly rival compressors when it comes to pressure increases, and even offer additional benefits.

The company was originally using two turbo compressors in its acid plant. One of them, stand - by was a slightly older version, which meant that spare part suppy could no longer be guaranteed. Procuring replacement parts would have been expensive, with long delivery times. The second turbo compressor repeatedly experienced vibration problems due to deposits on the impeller, meaning that operational reliability could not be assured.

The buying center of the acid plant decided to replace the older standby compressor with PILLER’s High-Performance Blowers and use it as the main compressor e.g. blower. After inquiring with several compressor manufacturers, their attention was attracted to the high pressure increase of the High-Performance Blowers by PILLER.

“Process operators of such plants are often only aware of compressors. The alternative of using a high-performance blower instead is never considered since customers assume that the required pressure increases could never be achieved by blowers,” states Dr. Steffen Kuberczyk, Head of Global Sales at Piller Blowers & Compressors.

To ensure the successful replacement of the compressors, requirements included increasing operational safety and minimizing downtimes

The turbo compressors were frequently switched off automatically because of excessively high vibrations. As tests showed, this was mainly due to deposits on the impeller. Vibrations put the drive bearings under severe strain, which in some cases can even lead to the destruction of the machine.

The solution:

Patented squeeze oil damper bearing of PILLER

Patented squeeze oil damper bearing of PILLER

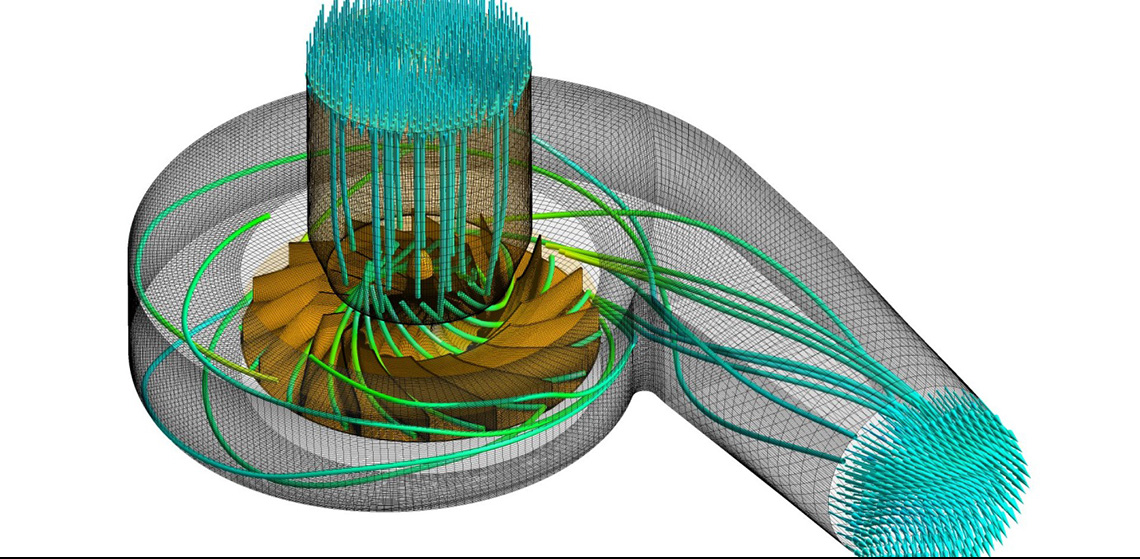

Thanks to its technology, the bearing system patented by PILLER – known as the squeeze oil damper – offers a large and resonance-free operating range and the possibility of working with certain imbalances such as those that occur through deposits/incrustations. The squeeze oil damper bearing system is very simple in its design and extremely reliable, with much lower maintenance requirements than with conventional compressor bearings.

Water injection

Water injection

PILLER High-Performance Blowers can optionally be fitted with suction-side water injection to prevent deposits on the impeller. This is usually used if the process is very humid and a relatively high amount of solids is pumped through the PILLER High-Performance Blower. Especially for this process of sulphuric acid production - based on liquid sulphur combustion - extremely dry process air is indispensable, therefore impeller cleaning by water injection can only be carried out if the plant is shut down during maintenance. In this case, water injection offers the advantage that maintenance is facilitated, as otherwise the impellers are usually cleaned manually.

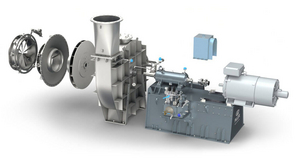

Blower design based on a modular structure

PILLER Blower Design

In addition, there was only a small and limited timeframe available for the compressors to be replaced. The installation of the PILLER High-Performance Blowers is possible thanks to their modular design with standardized components, which also allows customized requirements to be respected. This in turn results in much shorter delivery times than for compressors and makes the installation of PILLER High-Performance Blowers a kind of “plug-and-play” solution.

Machine availability: service- and maintenance-friendly

"In our decision to opt PILLER blowers, maintenance costs played a pivotal role", states Dipl. Ing. Zuzana Hechtová, Mechanical Technologist of the plant.

As part of its service and maintenance friendliness, the PILLER blower design boasts several other decisive advantages. Another benefit is the easy accessibility to individual components. This means that sealing rings can be replaced without even removing the impeller. Oil filters can also be changed during operation thanks to the use of switchable double filters. Should wear nevertheless occur during long-term operation, the impeller can be re-balanced during servicing and both the impeller and the casing can be re-welded on-site. This considerably reduces blower downtimes during maintenance and increases machine availability. After all, time and cost factors play a crucial role here, since when it comes to purchasing new production equipment, considerations go far beyond mere investment costs.

Correct dimensioning increases energy efficiency

Oversizing wastes energy. Often oversized blower or compressor systems are real energy guzzlers. This is not the case at PILLER where every blower is designed specifically for the exact operating data required by the customer. An accurate and adapted design of the blower system can lead to large energy savings. Since the efficiency varies greatly depending on the design point of different blowers and compressors, one should pay attention to the corresponding criteria already during the selection.

“Our high-performance blowers are not only replacing compressors in sulfuric acid plants – we’re receiving more and more inquiries for a wide range of processes across all sectors. Wherever compressors were previously used, our blower design and its myriad of advantages are now the prevailing choice,” adds Dr Kuberczyk.

A comparison of high-performance blowers with turbo compressors is certainly worth it!