Blowers and Compressors for MVR Processes

The principle of Mechanical Vapor Recompression (MVR) is used often in evaporators. It is an efficient solution to reintroduce the waste heat as a source of thermal energy for vaporization. In MVR applications our blowers and compressors provide energy recovery by compressing low temperature vapor to a higher pressure and temperature, so it can be re-used as a heating source. PILLER supports you to secure the optimum MVR vapor compression solution for your process.

Today, PILLER is the technology and market leader in the field of steam compression, using blowers and compressors. Our expertise of several decades offers a full service from engineering over project management to design and manufacturing.

More than 5,000 blowers for MVR

installed all over the world in various applications from beginning of the 1980's

Around 600 blowers for MVR

are currently manufactured per year

Advantages of our blowers and compressors for mechanical vapor recompression

Efficiency, flexibility, and reliability for the process industry

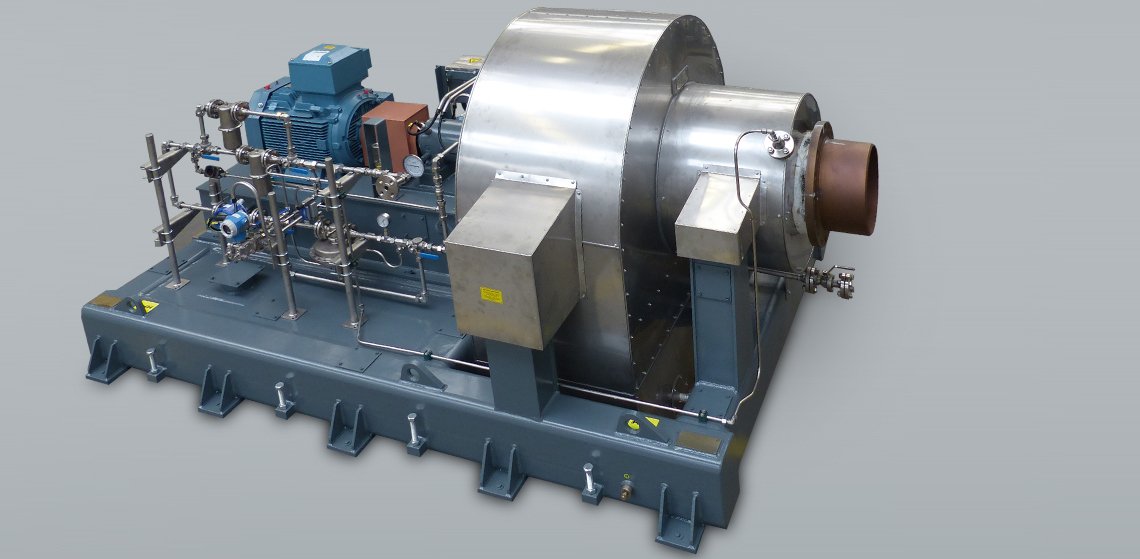

PILLER blowers and compressors are specifically developed and designed for Mechanical Vapor Recompression.

Our VapoLine achieves an efficiency of up to 87 percent.

They are more flexible, more reliable, require less maintenance, are less sensitive to sub-optimal process conditions, and are more robust than conventional (steam) compressors.

Our VapoLine for Mechanical Vapor Recompression are impressively powerful despite their compactness. They run with shaft powers of up to 6 megawatts at impeller speeds of up to 440 m/s. Depending on the particular installation, steam can be compressed to a pressure of up to 20 bar(g).

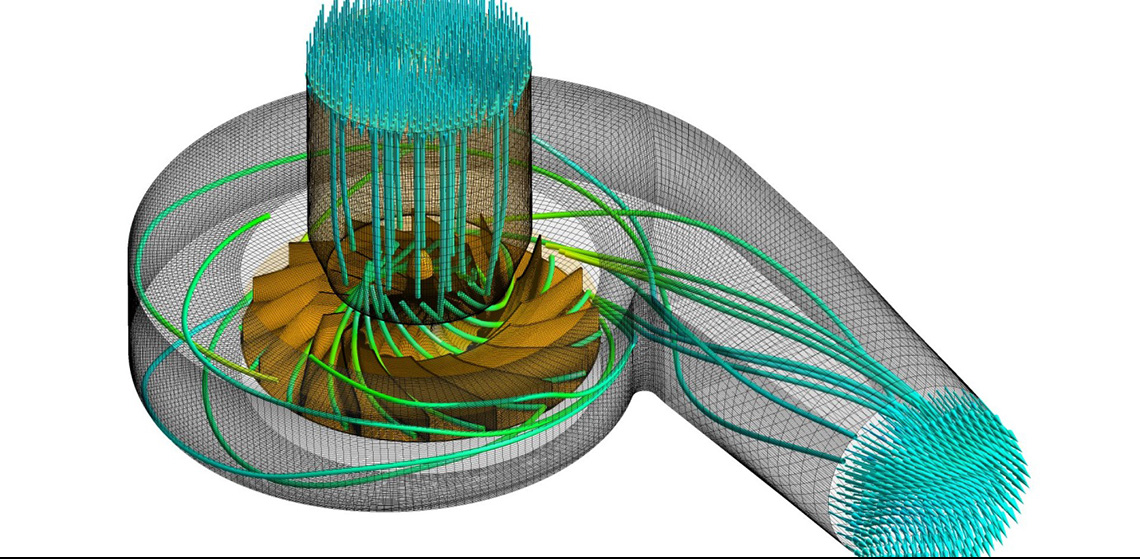

Using patented bearing technology, engineered high-performance impellers, and a continuous product improvement process, PILLER manufactures MVR blowers and compressors which provide customers maximum efficiency and durability, resulting in lower lifecycle costs.

All our activities are guided by our vision "ALWAYS ADVANCING". We act in the awareness of constantly developing our product portfolio for the best performance in all fields.

| Our VapoLine at a glance: |

|---|

|

Always Advancing

MVR BLOWER AND COMPRESSOR TECHNOLOGY FOR THE CHALLENGES OF YOUR PROCESS

PILLER MVR blowers and compressors have been used in industrial processes around the world for many decades. As industrial process requirements become more challenging, expertise must keep up with the pace. With our customized solutions at a high technical level, we meet the specific requirements of various industries with our vision "ALWAYS ADVANCING".

WHAT IS SO UNIQUE?

Our quality promise "Made by PILLER" means more than just quality components, manufacturing, and final testing. It also stands for decades of experience and expertise in engineering products for a wide range of process applications. We develop the perfect solution for your process conditions to ensure that our blowers and compressors meets your specific requirements. We will always engage you for your customer journey with expert knowledge, competence, and experience.

All developments are tested in our own MVR process plant and are used for quality assurance, endurance tests, and product demonstrations.

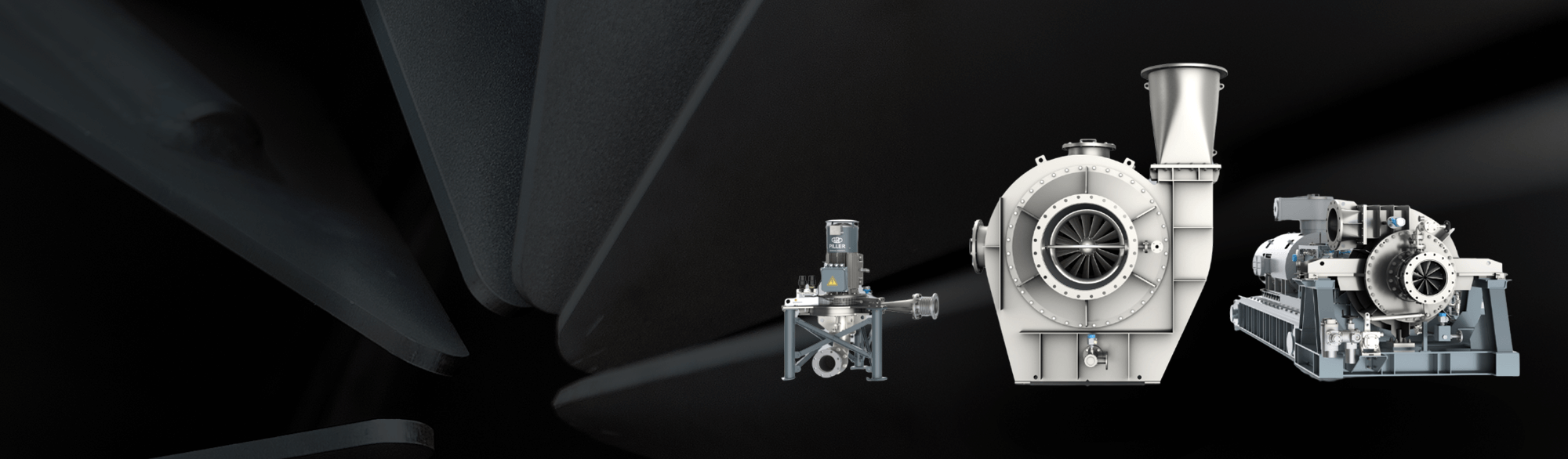

The PILLER VapoLine

MVR blowers and compressors for a wide range of processes and applications

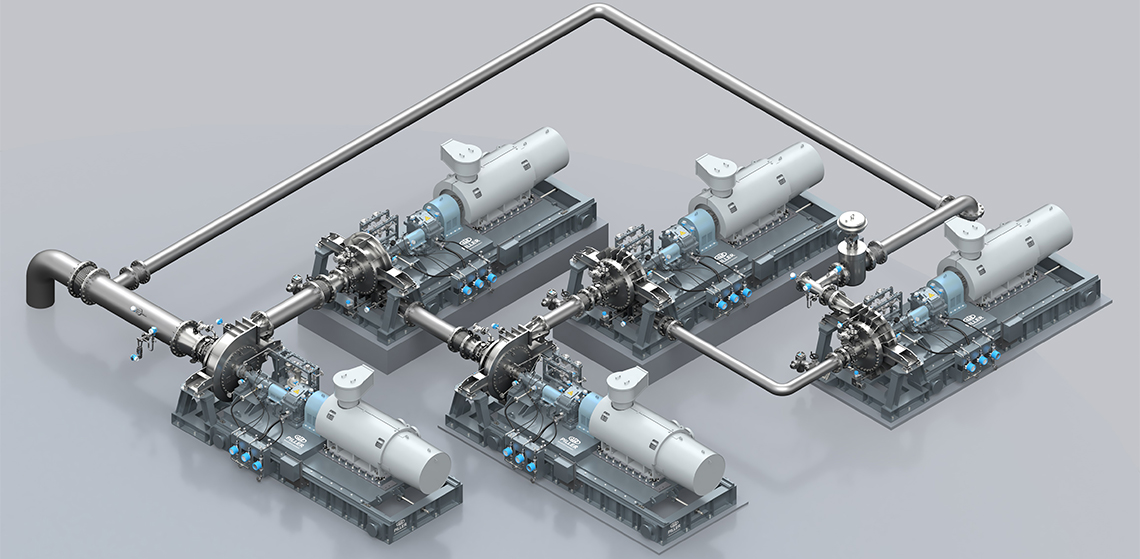

We specialize in customized solutions, starting with the VapoFlex, our key product. Our product range has grown considerably with the VapoFan covering low mass flows and the VapoMaxX for higher temperature lifts per-stage by using compressor performance.

The range of applications for MVR blower and compressor solutions is constantly expanding through implementation of new technology with our vision "ALWAYS ADVANCING". Today, it is possible to perform a temperature rise (ΔT) of up to 20 K with a single-stage application from PILLER.

Our specialists select the best solution from our PILLER VapoLine depending on your operating conditions and specific requirements.

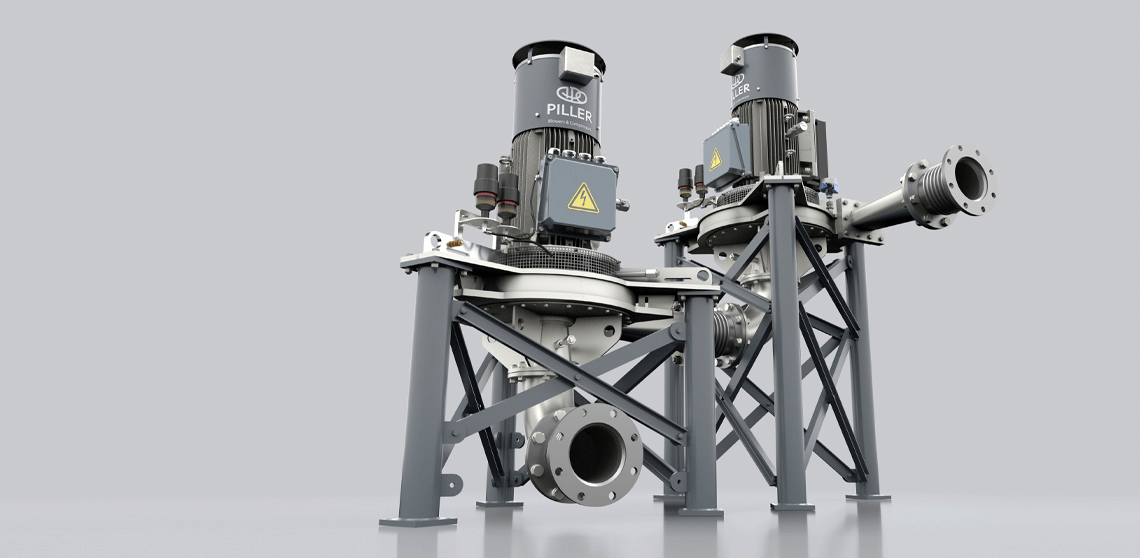

VapoFan

For low mass flows

With our VapoFan, we stand apart from the competition with a modular, compact unit for MVR applications in the mass flow range up to 9,000 kg/h and a temperature rise of 11K per stage. Where positive displacement compressors have often been used, the VapoFan is an excellent alternative as an vertical steam compressor, with better longterm durability, higher efficiency, and larger operating range. With this unique design, it can be easily integrated into existing processes.

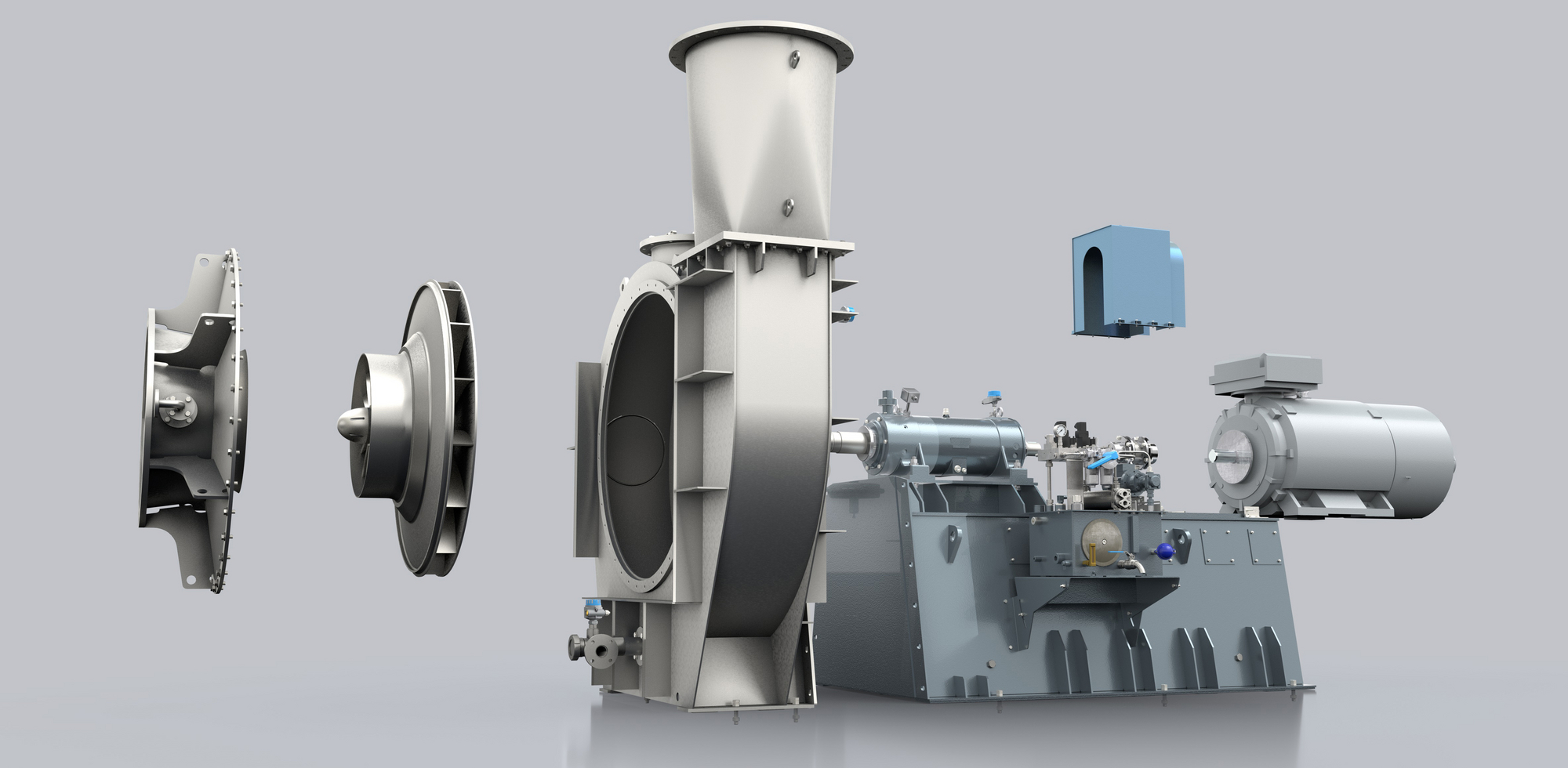

VapoFlex

Engineered-to-Order

Excellent performance, maximum efficiency, flexibility of implementation and operation with the reliability measured in the last decades are the hallmarks of our VapoFlex.

With broad capabilities we provide a wide variety of options. No two vapoFlex are alike. Our Engineered-to-Order (ETO) approach results in completely new designed, unique solutions. We design impellers, housings, components, and bearings to accommodate the desired mass flows of up to 250,000 kg/h with a temperature rise of 11K per stage.

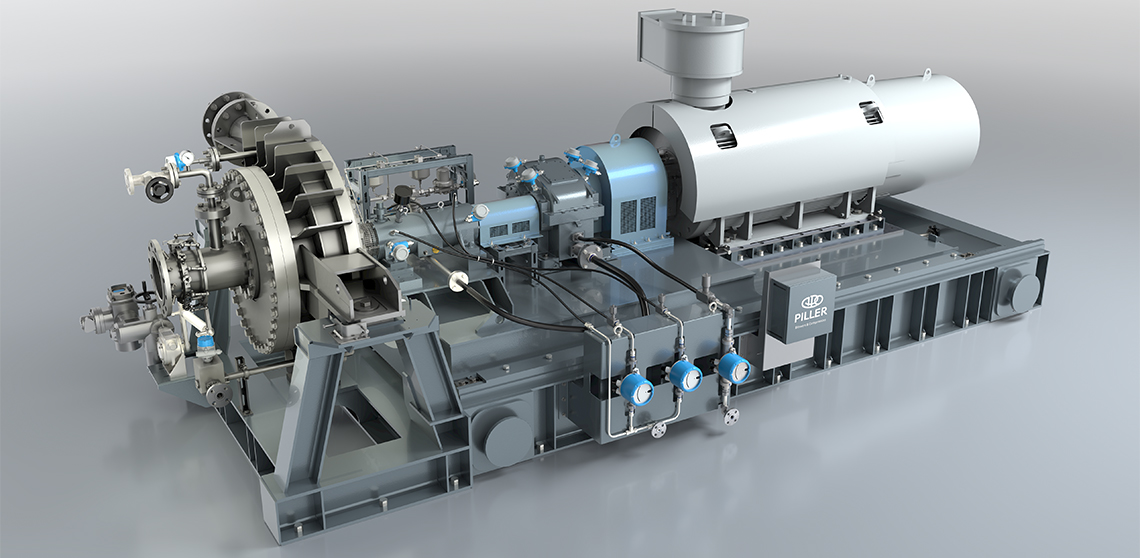

VapoMaxX

Smart compressor technology

Our newest product in the category of steam and vapor compression lives up to the "Made by PILLER" reputation for durability and quality, but it also offers a new range of performance that competes with turbo compressors. Pressures of up to 20 bar(g) and tip speeds of 440 m/s open new areas of application, resulting in temperature rises around 20K per stage.

Why is Mechanical Vapor recompression efficient for the process industry?

Redefining the level of reusing waste heat in the process industry

Large quantities of process steam are required in numerous industrial processes, particularly in the thermal separation of materials and products. Thermal separation processes such as evaporation or distillation are very energy-intensive and therefore also cost-intensive processes.

With the integration of Mechanical Vapor Recompression (MVR), not only energy costs can be reduced, but CO2 emissions can also be lowered. Mechanical Vapor Recompression is not only interesting from an economic point of view, but also in terms of CO2 reduction and the associated reduction in fossil fuels. The applications for MVR technology are almost endless and support you in a wide range of processes and applications to achieve your goals.

MVR blowers and compressors in the thermal separation processes

Thermal separation is a widespread technology in many industries. An effective measure to save energy, and reduce high steam consumption, is the implementation of Mechanical Vapor Recompression. This technology is used in a wide variety of applications such as distillation, crystallization and concentration. The waste heat generated by these processes is reintroduced as a heat source back to the process, where the Mechanical Vapor Compression is responsible for the temperature and pressure lift necessary to enable the heat transfer.

By offering the critical components of waste heat recovery processes, we are supporting industries to realize economic and environmental benefits. PILLER also offers system engineering services, including conceptual design as well as support in the Pre-FEED phase. Our blowers and compressors are precisely tailored to your vapor application.

Learn more about our wide range of processes and applications

Learn more about PILLER

Contact

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany

![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271