Bild mit Text

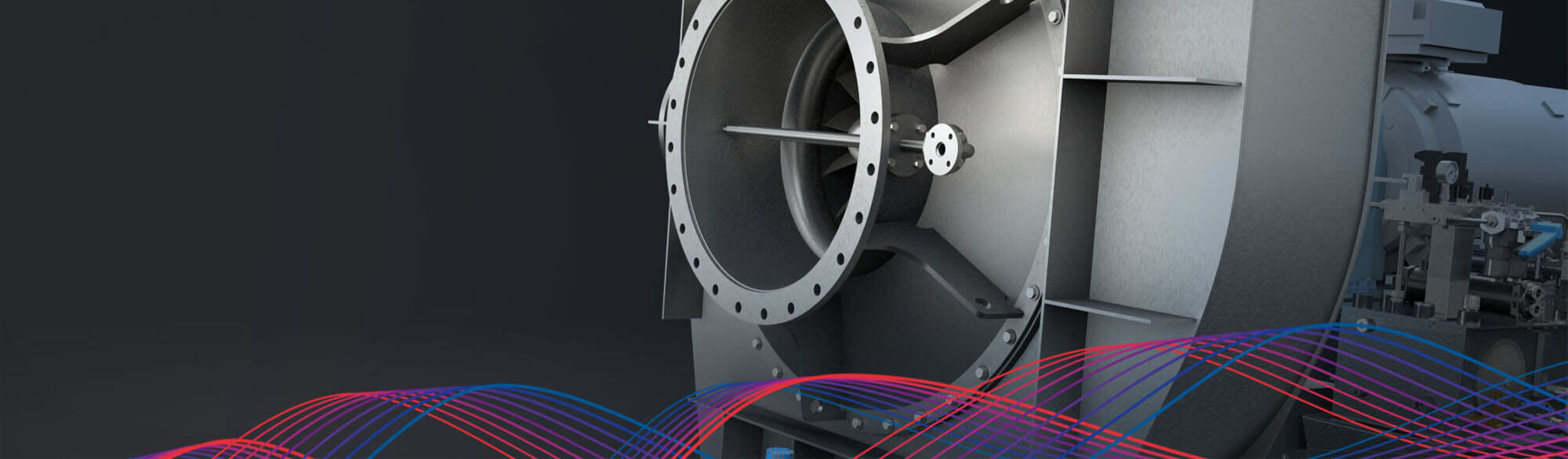

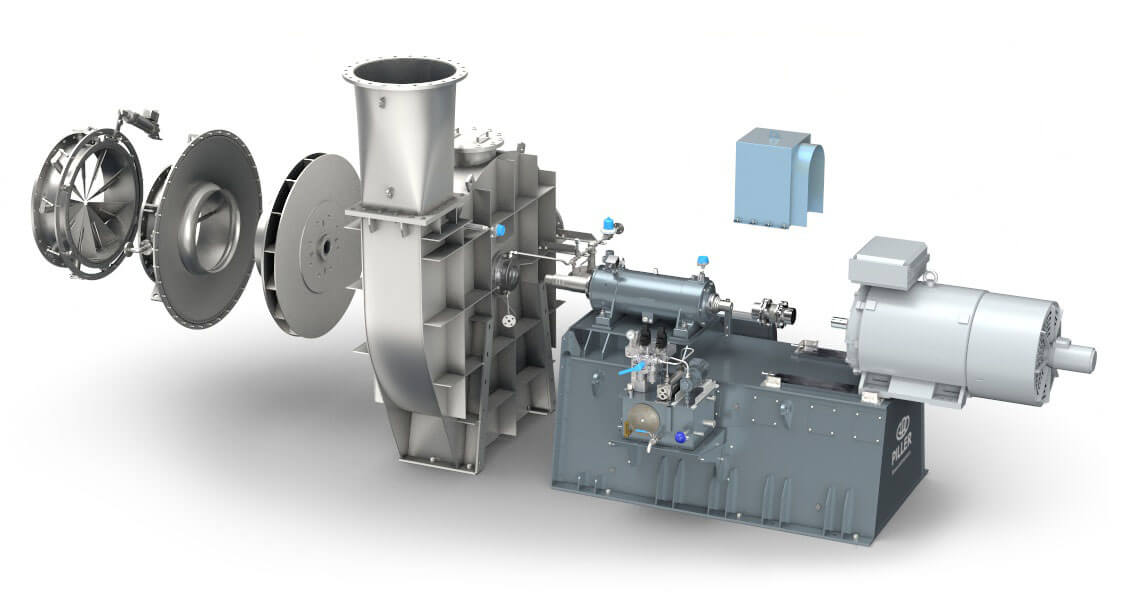

The development of state-of-the-art high performance blowers and compressors at Piller Blowers & Compressors includes a wide range of engineering and scientific disciplines. The mechanical limits of what is feasible can be completely exploited using modern materials and production methods.

Design methodology and the optimization of structural and fluid mechanics are productively employed to shift these limits. The control unit, drive and energy supply do their part in providing a reliable product that meets the demands required to be a PILLER machine.

The development of state-of-the-art high performance blowers and compressors at Piller Blowers & Compressors includes a wide range of engineering and scientific disciplines. The mechanical limits of what is feasible can be completely exploited using modern materials and production methods.

Design methodology and the optimization of structural and fluid mechanics are productively employed to shift these limits. The control unit, drive and energy supply do their part in providing a reliable product that meets the demands required to be a PILLER machine.

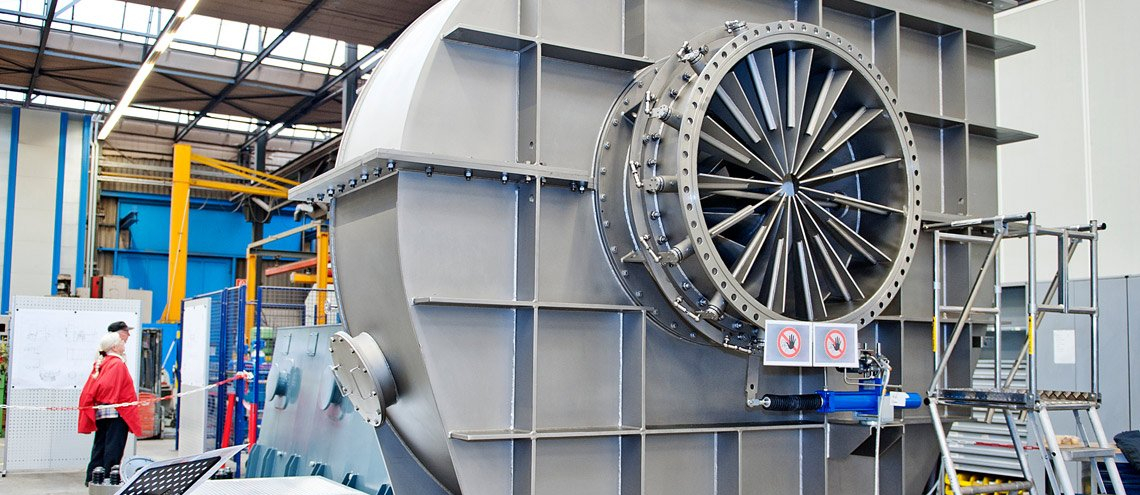

We manufacture customized blowers and compressors for the process industry and are one of the technology leaders. The name PILLER stands for top-quality products, for the spirit of innovation and for successful R&D. We are present internationally at trade fairs and through our subsidiaries – and there is hardly a country in the world that we have not delivered to.

With over 100 years of tradition, we have a mature corporate culture with special values.

Bildslider mit Text

Video mit Text

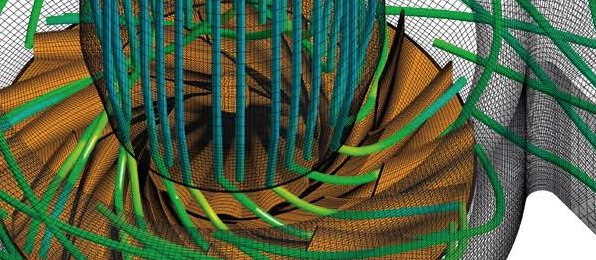

For good reason, PILLER counts among the international technology leaders for high-performance blowers and compressors.

Thanks to our experienced engineers and technicians, we offer process engineering expertise at the highest level. Our comprehensive service portfolio and our expert knowledge cover a wide range of applications, as well as individual, customer-specific solutions in almost every design. The top-quality products from PILLER are designed for various processes and the various sectors of the process industry.

Bild mit viel Text links

VapoFan

In addition to the variety of models, PILLER stands out from the competition with a modular, compact unit for steam compression in low mass flow MVR applications in the range of 200 to 5,000 kg/h. Where positive displacement compressors have often been used in the past, e.g. rotary lobe or Roots blowers, the VapoFan is a convincing alternative, employing unique technological advantages to provide a high-performance blower:

- compact, vertically arranged, high-performance blower with direct-coupled drive

- Temperature rise from 5 to 20 K

- Non-critical gap dimension (clearances), continuous flow, and constant efficiency

- completely constructed single-stage or two-stage solution

Our modular design – for short delivery times of only 10 weeks.

Produkte / Leistungen

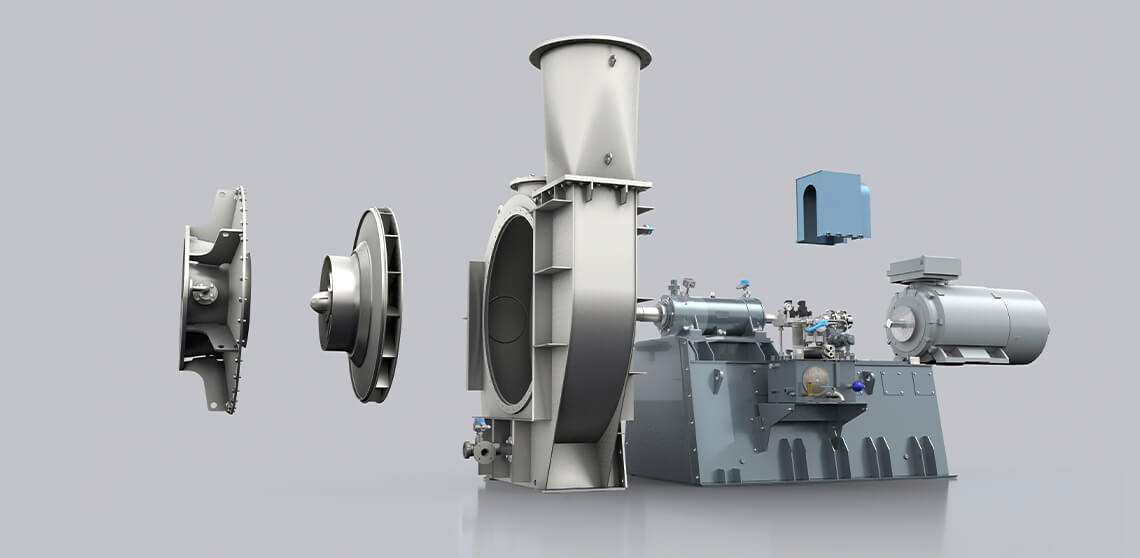

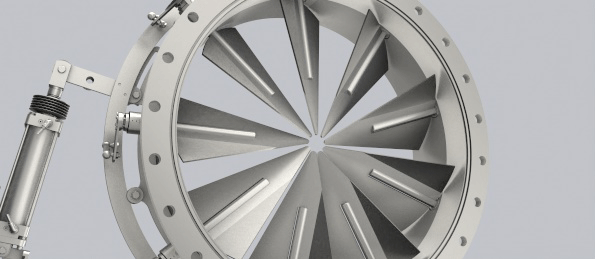

Inlet guide vane (IGV)

The inlet guide vane controls the operation by varying the stream into the blower. Usually electrical, pneumatic or hydraulic actuator are used.

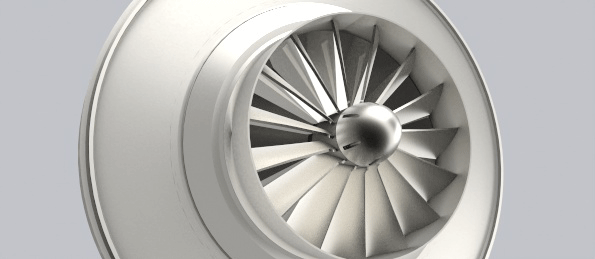

Impeller

There are over 2.500 different types and sizes for all kinds of applications; in any weldable metal, also with coating. Diameter from 400–2.800 mm, up to 1.000.000 m³/h and 60 kPa pressure rise.

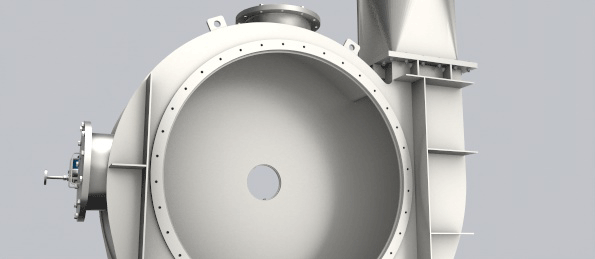

Casing

We manufacture casings exclusively as a welded construction, spiral casing with rectangular body shape. Optionally corrosion and/or pressure resistant and suitable for extreme temperature.

Niederlassungen

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany

![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271![]() pbc-info@piller.de

pbc-info@piller.de

Sales Areas: Europe, South America, Africa

Please contact Piller Headquarters in Germany in case sales areas are not listed on other sales offices.

Sales & Marketing Contacts

Piller BC Shanghai Ltd.

Unit 801-803

88 Keyuan Road, Zhangjiang Hi-Tech Park, Pudong

201203 Shanghai, PRC

![]() +86 21 50203878

+86 21 50203878![]() +86 21 50203876

+86 21 50203876![]() bcs-info@piller.de

bcs-info@piller.de

Sales Areas: Mainland China

Piller BC Shanghai Contacts

Piller Global (India) PVT Ltd.

“INFINITY House“

S/No 85 A-1/4, Lalit Estate Plot No 7,

Near Ganaraj Chowk, Baner Road,

Pune – 411045 (MH)

INDIA

![]() pgi-info@piller.de

pgi-info@piller.de

Sales Areas: India, Bangladesh, Bhutan, Nepal, Sri Lanka

Piller Global (India) Contacts

Ansprechpartner

Head of Marketing

Dipl.-Kffr. Ute Krupp-Leichtweis

Languages: ![]()

![]()

![]() +49 5554 201-346

+49 5554 201-346![]() +49 5554 201-271

+49 5554 201-271