11-stage compressor system for BASF

The heart of one of the world's most powerful heat pump systems is manufactured in South Lower Saxony

[Moringen, December 2025]

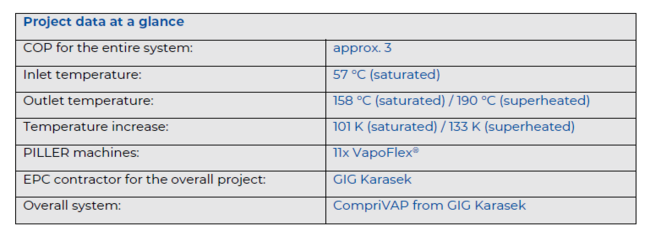

BASF is investing in one of the most powerful heat pump systems at its main facility in Ludwigshafen. The aim is to use waste heat from one of the largest production plants at the chemical site – Steamcracker II - as a thermal energy source for generating CO2-free steam. The use of this emission-free steam in formic acid production has the potential to reduce the greenhouse gas emitted by the process by 98 % in future.

PILLER supplies the heart of the system

The components from Piller Blowers & Compressors sit at the heart of one of the world's most powerful heat pump systems. The machines in the VapoLine® range from PILLER efficiently compress vaporous waste heat from industrial processes, thereby bringing it to a usable temperature level – the basis for the heat pump function. PILLER supplies six VapoFlex® machines (line 1) and five further VapoFlex® machines (line 2) – for steam generation. The system comprises a total of 11 compressor stages, including the electrical drive systems and the corresponding accessory components. Delivery is scheduled for mid-2026. The system requires maximum compressor capacity and will compress around 500,000 tons of steam per year. Beside the technologically advanced machines with impeller diameters of up to 2.25m, the system is equipped with a modern operating point monitoring system. The operator is informed when limits are reached or exceeded here, so that maximum machine availability can be secured.

The project is being realized at BASF together with plant manufacturer GIG Karasek. The CompriVAP system from GIG Karasek combines proven components, namely a plate falling film evaporator, flash tank, and the PILLER compressor cascade, in order to create a pioneering overall technological concept. Thanks to its hybrid design, it produces completely oxygen-free steam and uses pure water as a safe and environmentally friendly working medium. The flexible operation with infinitely variable partial load capacity and electricity price-optimized start-stop cycles enables economical operation, while intelligent condition monitoring increases availability and reduces maintenance costs.

PILLER in the process

The innovative steam compression system sets new standards in terms of both the efficiency and quality of steam generation. In a first step, waste heat is used in a flash cycle of GIG Karasek to generate flash steam under vacuum conditions. This steam is then compressed to a pressure above atmospheric pressure by six VapoFlex® arranged in series (line 1). A key requirement for the downstream process is to avoid ingress of even minimal quantities of atmospheric oxygen. For design reasons, meeting this strict process requirement is a complex undertaking for the system comprising compressors and connecting pipelines in the vacuum area. A concept with an intermediate heat exchanger in the form of a customized plate falling film evaporator from GIG Karasek was therefore selected. This prevents atmospheric air from entering the downstream process. The newly acquired live steam in the intermediate heat exchanger, which is at above atmospheric conditions, is then compressed to the required pressure and temperature level by five further VapoFlex® units arranged in series (line 2). The result: up to 60 tons of steam per hour.

BASF and PILLER have a longstanding partnership, in which multiple vapor recompression plants have already been equipped with machines from PILLER. Beside these, PILLER has already successfully supplied similar multi-stage/heat pump concepts to other customers in the chemical industry outside Europe in recent years. The company is both proud and pleased to be able to use its extensive expertise for the benefit of the German chemical industry. The advanced compression system not only ensures high efficiency and quality, but also a reliable supply of steam and high availability in the overall CompriVAP system, thereby meeting BASF's specific requirements.

Christoph Böhnisch, CEO at PILLER, adds: "Our VapoLine® compressors are already being used in many heat recovery projects throughout the world. However, the BASF project is something really special for us. Seeing our expertise in the pilot project in Germany and working together to shape the transformation fills the entire company with pride."

Milestone for the green transformation

While the green transformation is becoming increasingly important across all industries, it is a clearly defined strategic focus for BASF. One key to this is the use of industrial waste heat. The compressor technology of the VapoLine® efficiently raises waste heat vapor to a higher temperature level. The energy can then, for example, be used directly in production, which increases efficiency and reduces CO₂ emissions – thereby boosting both competitiveness and sustainability.

This project is a milestone, as Andreas Schnitzhofer, Managing Director at GIG Karasek, is keen to stress: "This is a game changer for us. Today, waste heat often remains unused or is cooled down at great expense. However, it is actually a valuable resource and a genuine alternative to fossil fuels. Our solution uses this energy source efficiently. The investment is typically amortized after two to three years.

"The target groups are all companies in the chemical industry, as well as other industries where energy efficiency and CO₂ reduction play an important part. The demand is immense: The German industrial sector alone consumes around 544 TWh of process heat¹ every year, with a significant proportion still being covered by fossil fuels.

BASF is set to reduce CO₂ emissions by up to 100,000 tons per year thanks to this project. This is an important step on the road to net zero CO2 emissions by 2050. Thanks to the scalability and adaptability of the overall system, numerous applications with various waste heat sources are possible. The BASF project shows the great potential of industrial waste heat utilization and can inspire other industries to implement similar solutions for CO₂ reduction.

In summary, it is fair to say that BASF is focusing on innovative technologies in order to open up new paths in the sustainable provision of process heat in the course of the industrial transformation. Among other things, focus is on the use of high-temperature heat pumps, which offer considerable potential for reducing primary energy consumption and CO₂ emissions through use of waste heat and high efficiency levels – even under the current framework conditions of the electricity mix. Against this backdrop, the technological progress that BASF is driving forward in pilot projects is an important building block on the road to decarbonizing industrial processes.

(Source: Deutsche Gesellschaft für Internationale Zusammenarbeit GIZ GmbH, "Industrial high temperature heat pumps in Germany and Europe - potentials, application cases, and support policy", December 2022)

[Characters, inculding spaces: 7.324]

---

About Piller Blowers & Compressors

Piller Blowers & Compressors GmbH, based in Moringen, develops, designs, and manufactures customer-specific blowers and compressors for the process industry. The roots of the family business go back to 1909.

PILLER offers efficient and economical solutions for customers in many industries, including the food & beverage, pulp and paper, chemistry, petrochemistry, pharmaceutical, and industrial wastewater treatment, with customized designs or appropriately configured machines. PILLER also supports customers with innovative heat recovery technology on their path to sustainable production. Compressors for the process industry can achieve up to 75 percent reduction in energy consumption, over 60 percent reduction in CO2 emissions, and up to 90 percent savings in energy costs.

PILLER offers a full range of services from engineering and project planning to design and manufacturing, as well as comprehensive services including commissioning, training, inspection, repair, and system optimization. With continued investment in research and development, PILLER is constantly working to push the boundaries of the already high efficiency, power availability, and long service life of its machines.

With 528 employees and branches in the USA, Singapore, China, and Australia, as well as joint ventures in Korea, India, and Brazil, PILLER now has an international presence. The group's turnover in 2024 was around 130 million euros.