High-Performance Blowers and Compressors

Made with engineering expertise

The development of state-of-the-art high performance blowers and compressors at Piller Blowers & Compressors includes a wide range of engineering and scientific disciplines. The mechanical limits of what is feasible can be completely exploited using modern materials and production methods.

Design methodology and the optimization of structural and fluid mechanics are productively employed to shift these limits. The control unit, drive and energy supply do their part in providing a reliable product that meets the demands required to be a PILLER machine.

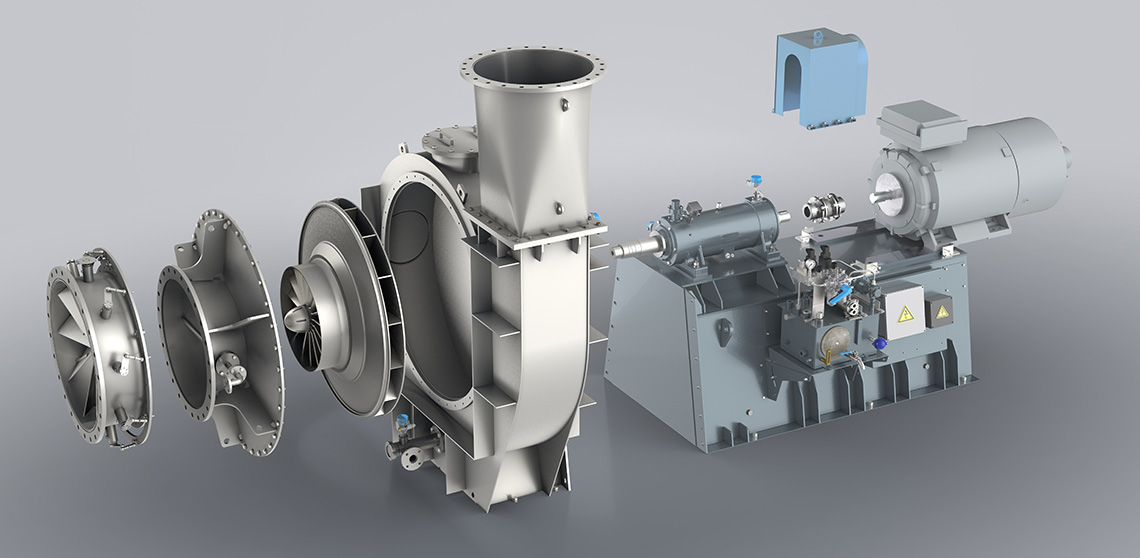

Centrifugal Blower design

Premium components for efficient performance

All blowers and compressors are custom-designed by us. Performance, reliability and cost-effectiveness are the main criteria in the design.

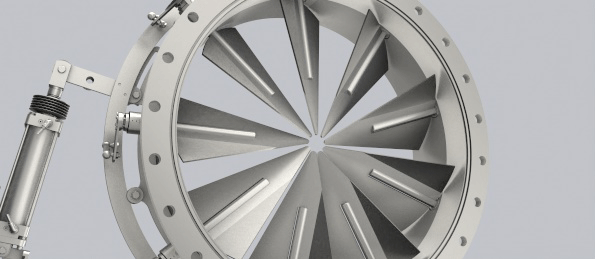

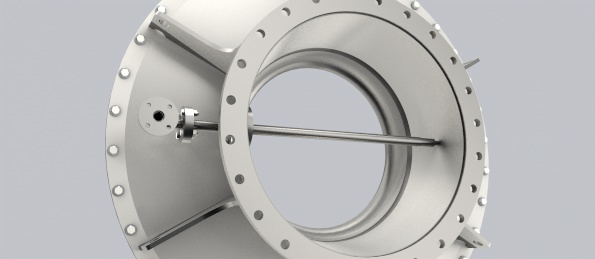

Inlet guide vane (IGV)

The inlet guide vane controls the operation by varying the stream into the blower. Usually electrical, pneumatic or hydraulic actuator are used.

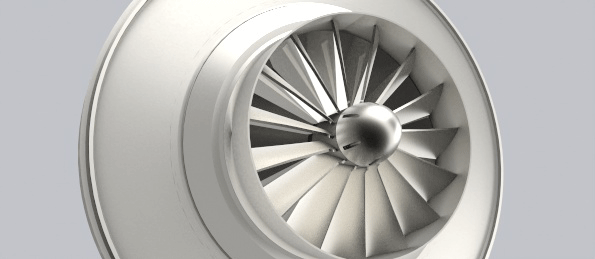

Impeller

There are over 2.500 different types and sizes for all kinds of applications; in any weldable metal, also with coating. Diameter from 400–2.800 mm, up to 1.000.000 m³/h and 60 kPa pressure rise.

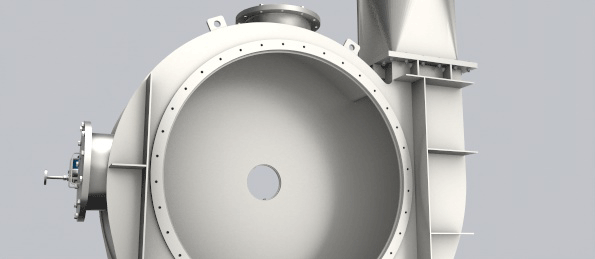

Casing

We manufacture casings exclusively as a welded construction, spiral casing with rectangular body shape. Optionally corrosion and/or pressure resistant and suitable for extreme temperature.

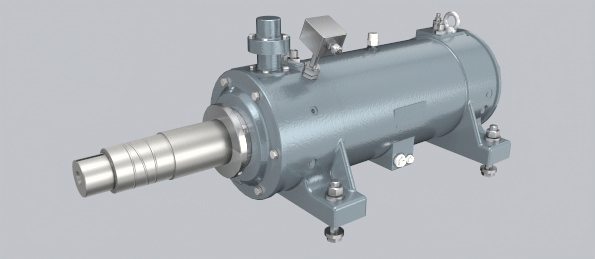

Motor

The motor drives the blower. Electrical motor, steam turbines or combustion engines can be used. PILLER picks always the best and most efficient for the customer.

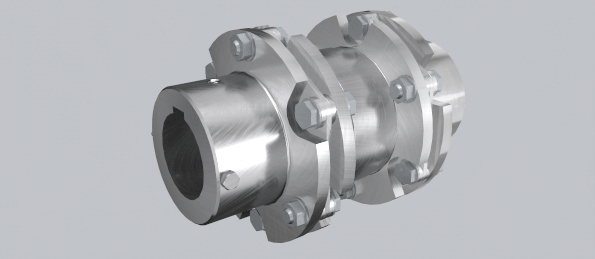

Coupling

The coupling connects the drive with the impeller of a blower. PILLER uses only couplings from renowned suppliers such as Siemens Flender, John Crane Metastream, who can give global support.

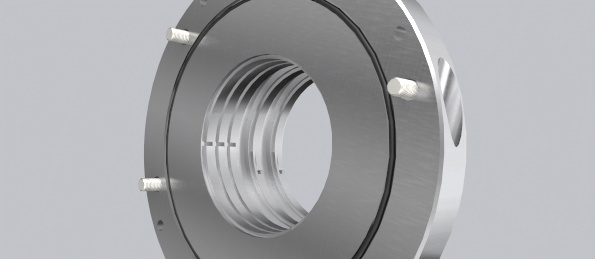

Shaft Seal

The shaft seal minimizes the leakage in the shaft tunnel. Depending on the application different types of shaft seals are recommended. From felt rings or packing gland over floating carbon rings to dry gas seals.

Bearing

The bearing has to carry the full load of the impeller weight. For an efficient and smooth operation, depending on customer demand or application, either anti-friction or fluid film bearings are used. PILLER’s patented squeeze oil damper bearing combines the advantages of both types.

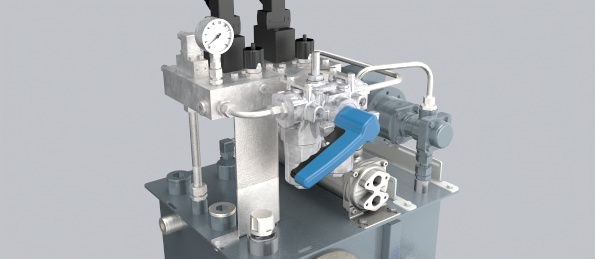

Lube oil unit (LOU)

Standardized or customized high-quality lube oil units guarantee optimum lubrication. Specific customer requirements can be realized by PILLER at any time.

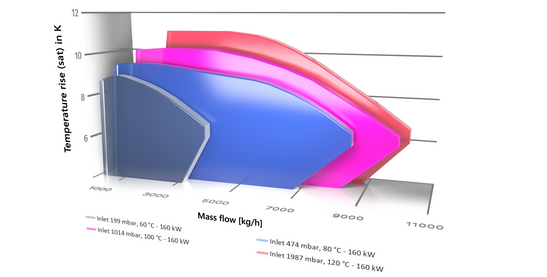

Water injection

With a controlled water injection on the suction side of the blower, PILLER reaches highest efficiency: besides a cleaning effect, the steam is desuperheated and provided as saturated steam, increasing the heat transfer.

Key blower parts

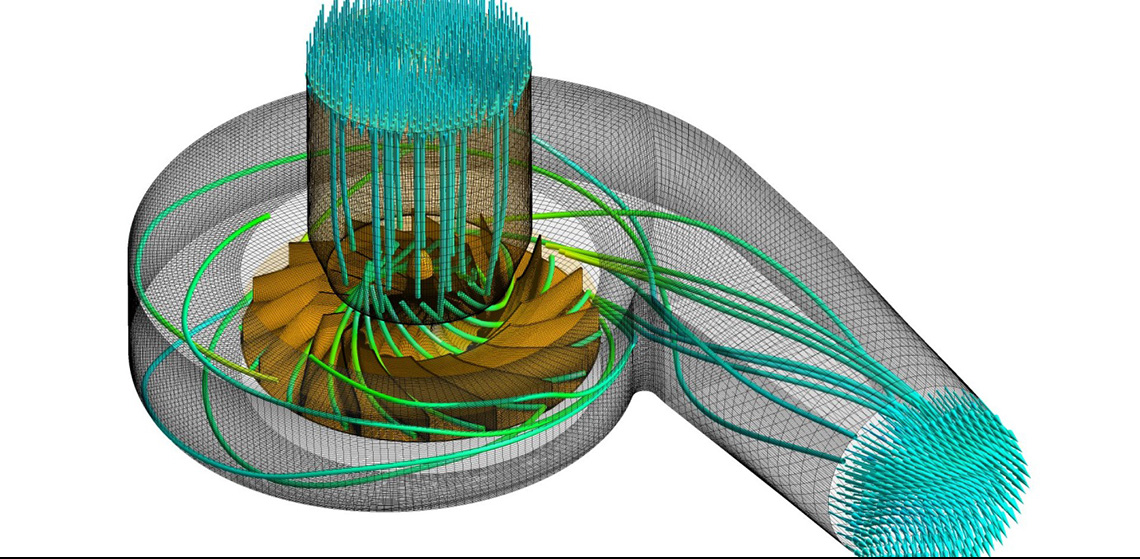

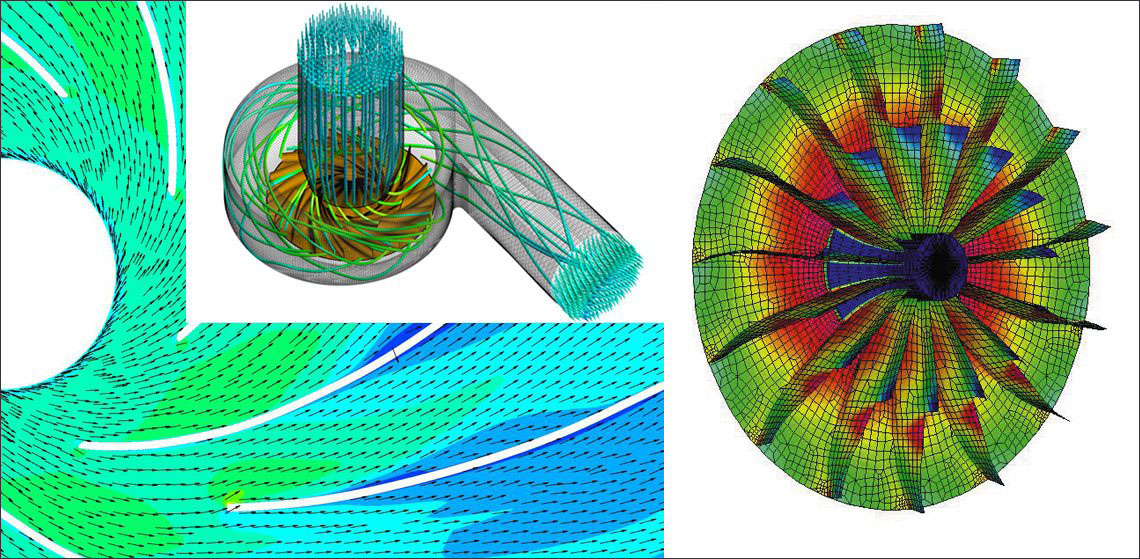

Impellers – The core to every blower setup

Our R&D engineers give their all to optimizing the performance of impellers in all relevant parameters. State-of-the-art technology for the process industry of tomorrow – that is our claim.

It determines the performance and meets the requirements of the customer with regard to volume flow, pressure increase and efficiency.

Our impellers are constantly improved by means of optimum fluid mechanics design, numerical optimization and metrological validation. We always consider the interaction between an optimum fluid mechanics design and the structural-mechanical configuration.

Individual blower casings for multiple applications

Developing casings so that design and construction are exactly matched to the desired impellers and their application – that's what distinguishes the engineers in our R&D department.

The casing has an enormous task:

To decelerate the flow leaving the impeller – from speeds in the ultrasound range to around that of a Formula 1 car on the long straight – and to do it on the shortest possible route.

The dynamic pressure that builds up in the impeller is converted into static, and therefore usable pressure, by delaying the flow.

The machine can only meet all the performance requirements when the sizing and design of the casing are perfectly matched to the selected impeller.

High quality coatings – for maximum functionality and durability of centrifugal blowers

For maximum functionality and durability, PILLER uses a wide variety of coatings and surface treatments – precisely tailored to the respective process requirements.

The use of our blowers and compressors in the different industrial processes makes high demands on surfaces.

Depending on your needs, we recommend different coating solutions for individual requirements.

Corrosion Protection

Depending on the medium and temperature, different coatings are used, such as rubber coatings, synthetic fluoride coatings, or carbon fiber reinforced plastic coatings.

Reduction of adhesion

Surface treatments such as electropolishing, vibratory grinding or even a synthetic fluoride coating are used to avoid imbalances caused by adhesion of the medium. Smooth surfaces are also required in the food and medical equipment industry in order to avoid contamination in the surface structure.

Wear Protection

The easiest wear-protection measure is to increase the thickness. If this is insufficient to achieve acceptable service lives, either the base material of the component is coated or wear plates, which can also be coated, are used. Influencing factors such as particle size, flow rate or chemical attack of the material define the type of coating and therefore the processing method, such as the flame-spray method, arc spraying processes, build-up welding or plasma-powder overlay welding.

Increased Rigidity

Strength blasting can be used for impellers subject to high stress loads in order to reduce the peak voltages in the impeller.

More about centrifugal blowers

Contact

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271