ALWAYS ADVANCING

Learn everything you need to know about the PILLER VapoLine in our Webinar.

PILLER offers reliable high-performance blowers and compressors for your MVR system. Our solutions stand for maximum efficiency and durability as well as cost-effective and easy commissioning.

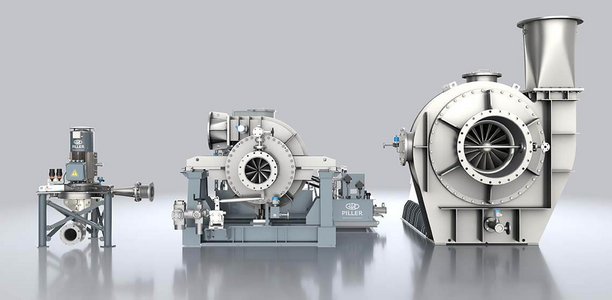

The choice of our MVR product portfolio "VapoLine" ultimately depends on operating conditions, i.e. the mass flow, the temperature differential and compression ratio.

The PILLER VapoFan, VapoFlex and VapoMaxX generate outstanding single-stage performance, but these can also be combined into powerful multi-stage systems. Thus, higher temperature rises can be achieved, especially in vapor compression heat pump systems for waste heat recovery.

In our webinar you will learn why the PILLER VapoLine products are the optimal solution for your MVR system and offer an excellent chance to save energy and reduce carbon emissions.

Our PILLER VapoLine products offer the optimal solution for your process conditions and provide an opportunity to save energy and reduce carbon emissions.

Get detailed information in our VapoLine webinar about our solutions with application examples, operating ranges, maintenance instructions as well as possibilities for CO2 reduction of your plant.

Looking for efficient blower or compressor technology for your MVR system?

Join our next VapoLine Webinar!

There are currently no planned dates for this webinar.

In the meantime we offer individual presentations for you and your team. Our experts will provide you with detailed information on our products and solutions and answer your questions.

Just send an e-mail to pbc-marketing@piller.de and schedule a meeting.

Dr. rer. nat. Steffen Kuberczyk

Chief Sales Officer

At PILLER, we ensure innovation and top product quality. We offer customized, efficient solutions.

Our VapoLine product portfolio is specifically developed and designed for Mechanical Vapor Recompression (MVR) applications.

PILLER was the first company to introduce centrifugal blowers for Mechanical Vapor Recompression (MVR) in the 1980s. To find the perfect match for your process conditions, we will engage you with expert knowledge, competence, and experience.

We specialize in customized solutions, starting with the VapoFlex, our flagship product line. Our range of performance has grown considerably with the VapoFan covering lower mass flows and the VapoMaxX, extending our singlestage performance capability using compressor technology.

Our in-house R&D is dedicated to continuous, cutting edge product development, such as the self-invented squeeze oil damper bearing systems. Consequently, our products are of exceptional quality standard and smart design.

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271