ALWAYS ADVANCING

Learn everything you need to know about the PILLER VapoLine in our Webinar.

Since 2020, we have been offering regular webinars for our products.

In our webinars you will receive detailed information about our solutions with

Operators who are looking for new and efficient

solutions for steam compression

Our PILLER VapoLine products offer the optimal solution for your process conditions and provide an opportunity to save energy and reduce carbon emissions.

Get detailed information in our VapoLine webinar about our solutions with application examples, operating ranges, maintenance instructions as well as possibilities for CO2 reduction of your plant.

Are you looking for a rotary lobe compressor alternative? Our blowers offer the same performance, with guaranteed advantages!

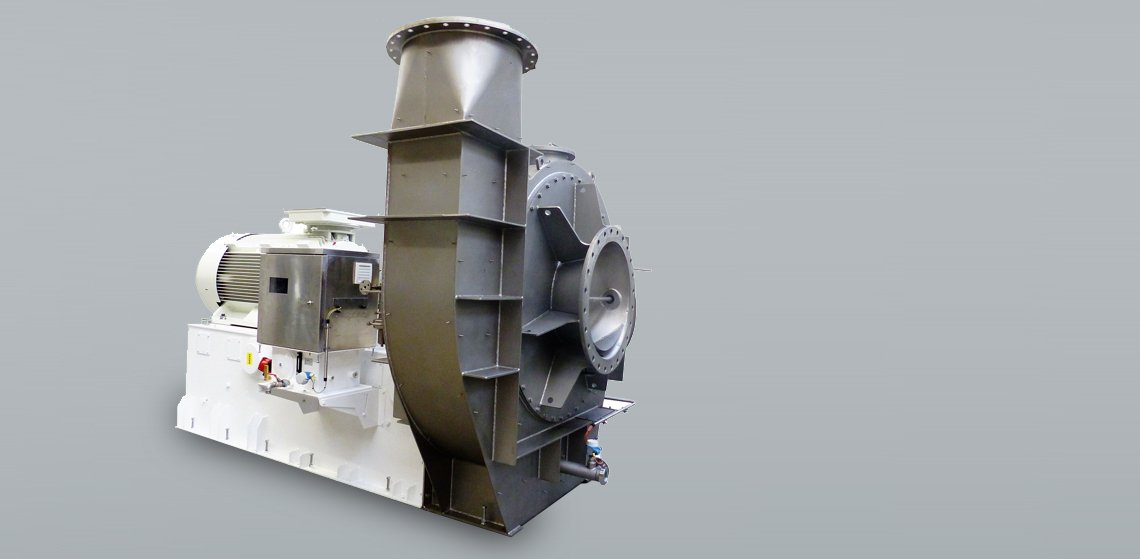

The PILLER VapoFan is a steam compressor designed for mass flows from 200 to 9,000 kg/h. Due to its modular design, it can be easily customized to fit into existing systems.

Our webinar provides you with detailed information about possible applications, technical product features and maintenance instructions.

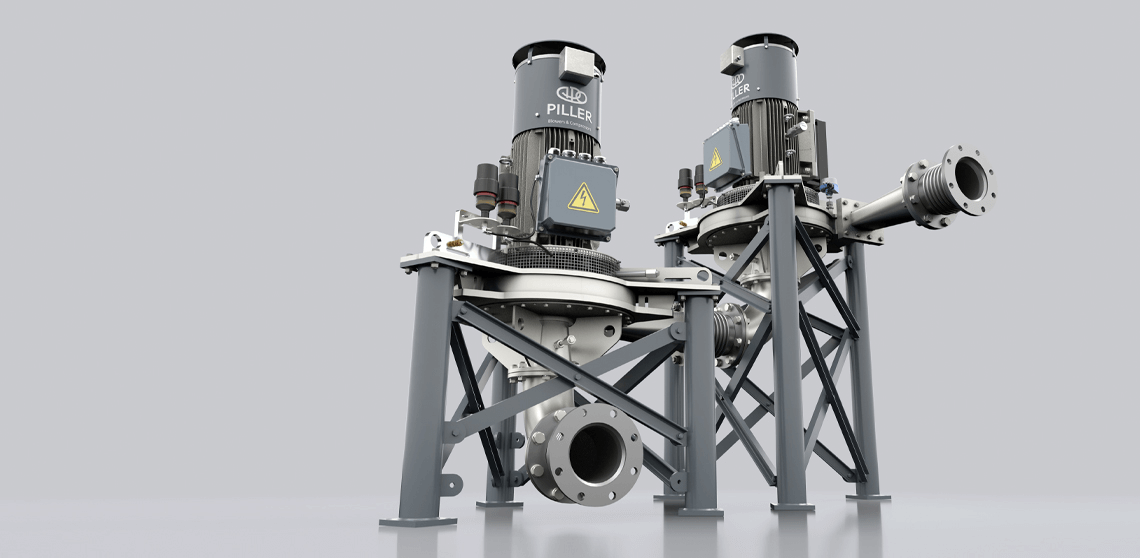

The PILLER VapoMaxX is a high pressure and high temperature compressor for vapor and steam applications. Our machine combines the advantages of our high-performance blowers and the advanced performance of compressor technologies with guaranteed benefits!

The VapoMaxX is designed for applications with a maximum mass flow of 57,000 kg/h, up to 20 bar pressure and temperatures up to 215 degrees Celsius.

Our webinar provides you with detailed information about possible applications, technical product features, maintenance instructions as well as possibilities fro CO2 reduction of your plant.

We offer individual presentations for you and your team. Our experts will provide you with detailed information on our products and solutions and answer your questions.

Just send an e-mail to pbc-marketing@piller.de and schedule a meeting.

In just 60 minutes you will get to know the product, the most important features, and the relevant applications.

Call in and learn - whether at your workplace or mobile: PILLER provides you with global access.

We at PILLER have the highest regard for quality, our products, as well as for customer service and support.

At the end of each live webinar, we will take the time to answer your questions in detail.

More than 100 years of experience with blowers and compressors

Piller Blowers and Compressors is a traditional family owned business – with expertise and experience. As the technology leader in steam compression, we supply our blowers to original equipment manufacturers and plant engineering companies all over the world.

The MVR blower for low mass flows

The VapoFan is a high-performance vertical steam compressor. With its compact and modular design, it can be easily integrated into existing processes.

Piller Blowers & Compressors GmbH

Nienhagener Str. 6

37186 Moringen

Germany![]() +49 5554 201-0

+49 5554 201-0![]() +49 5554 201-271

+49 5554 201-271