PILLER makes it possible to use the surplus heat by bringing gaseous waste heat flows to a usable pressure and temperature level by direct compression or by generating steam in a resource-saving manner.

When used in the energy-intensive process industry with high steam demand, the system has proven itself in terms of cost-effectiveness and sustainability. Our system can be installed wherever thermal separation processes take place and surplus heat is generated. The PILLER Industrial Heat Pump impresses with significant energy savings and an enormous reduction of CO2 emissions.

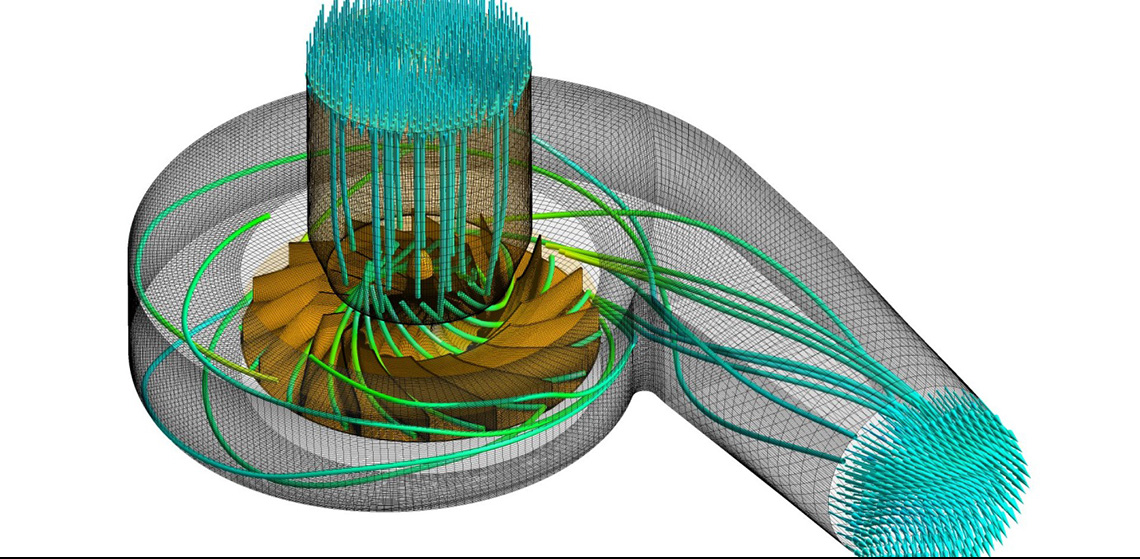

We use classic vapor compression or a heat pump circuit with evaporator to generate steam. This steam is compressed to the required temperature level by PILLER High Performance Blowers, thereby allowing this energy to be reintroduced into the process or elsewhere in the plant.

The advantages are clear: higher energy efficiency due to the reuse of waste heat, reduced use of fossil fuels, lower CO2 emissions and reduced energy costs – thanks to retrofitting your process.

As usual, we design the components according to the process data you specify. For the most efficient and economical solution. For your success.

Learn more about the PILLER Industrial Heat Pump and its possibilities or contact our experienced engineers for comprehensive advice.